What are the key challenges in machining biotech parts for lab automation?

Making parts for laboratory automation systems is hard since it goes beyond what is normally done in machining. These problems come from the biotech industry's strict standards and the fact that the parts are hard to work with.

Micron-level Precision and Consistency

One of the hardest things about CNC machining biotech parts is getting and keeping micron-level accuracy across runs. Lab automation equipment often works with very small amounts of samples and chemicals, so its parts need to be able to withstand very high temperatures. For example, lab-on-a-chip devices may need tolerances as small as ±0.001 mm for microfluidic pathways to work properly so that fluid flows smoothly and correctly.

Biocompatibility and Chemical Resistance

Another significant challenge is the selection and processing of materials that are resistant to several chemicals while also being biocompatible. There must be zero tampering with the samples or the experiment's outcomes. Materials like high-quality stainless steels, titanium, or custom-made polymers like Polyether Ether Ketone (PEEK) are ideal for this use. They can be challenging to create due to their uniqueness. Specific cutting instruments and techniques are required.

Surface Finish and Cleanliness

It's very important that biotech parts have a good surface finish so that they stay clean and automatic systems work right. Nanometers are usually used to measure how smooth something is. To get the right amount of smoothness, you need to use modern machining techniques and be very careful with quality control. Also, there are special ways to clean and handle these parts after they have been machined so that they stay in perfect shape and don't get contaminated and change the results of tests.

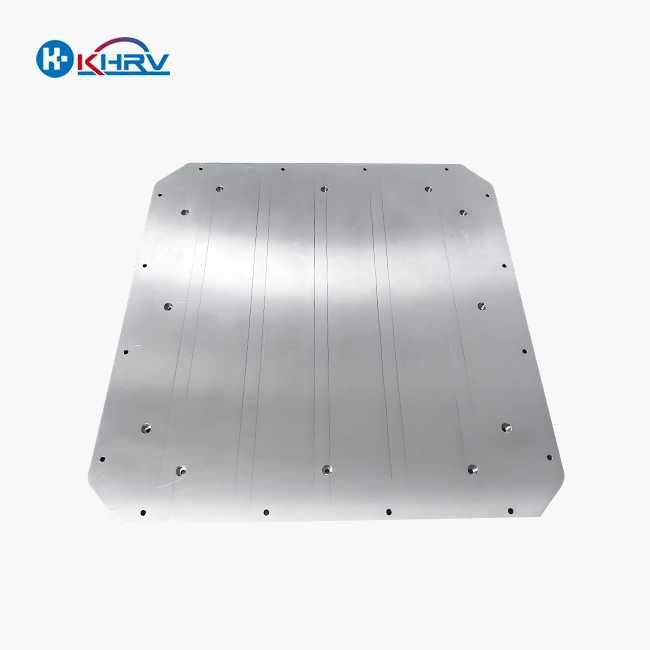

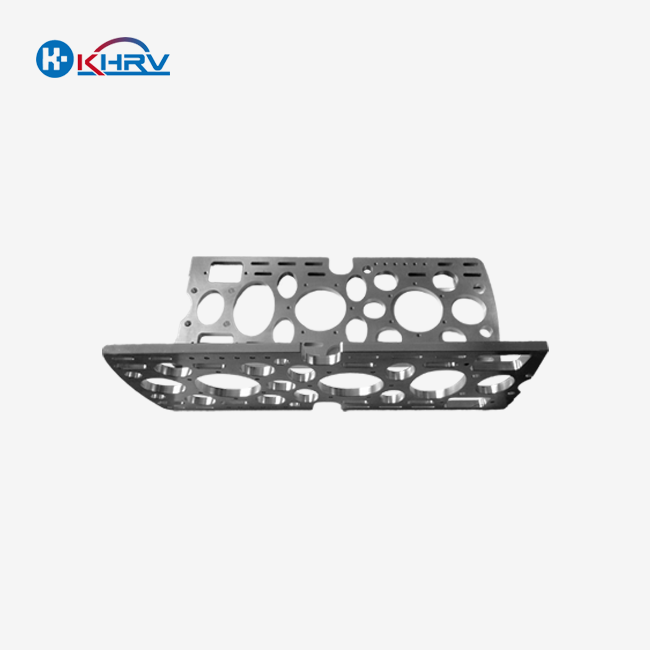

Complex Geometries and Features

Many parts of laboratory automation have complex shapes and characteristics that go beyond what standard machining can do. These could be internal channels for moving fluids, undercuts for sealing surfaces, or complex designs for sampling wells. To machine these kinds of features, you need extensive CNC programming, multi-axis machining centers, and occasionally tools that aren't normally used.

Design considerations for fluid-handling components in biotech CNC machining

When designing fluid-handling parts for biotech applications, it's important to find the right balance between usefulness, manufacturability, and meeting industry requirements. These parts are what make laboratory automation systems work. They are in charge of moving and controlling liquids in experiments and analyses with great accuracy.

Material Selection for Optimal Performance

Picking the right material is very important when making parts that deal with fluids. The material that is chosen must be able to stand up to the chemicals and living things that will be around it and keep its shape over time. These are some popular alternatives:

- 316L Stainless Steel: Prized for its corrosion resistance and durability

- PEEK: Offers excellent chemical resistance and low protein binding properties

- Fluoropolymers, like PTFE and PFA, are great for uses that need to be completely chemically neutral.

Choosing the right material affects both how well the part works and the cutting techniques that are used to make it.

Optimizing Flow Dynamics

Fluid-handling components must be designed to optimize flow dynamics, minimizing turbulence and dead zones where samples or reagents could accumulate. This often involves:

- Smooth transitions between channels and chambers

- Gradual bends to reduce pressure drops

- Polished internal surfaces to reduce friction and prevent adhesion

CNC machining is a key part of making these design features possible. To make complex internal shapes, multi-axis machining and specialized tools are often needed.

Sealing and Connection Interfaces

Important design factors include the points where fluid-handling parts join to other parts of the system. These places must make sure that the system doesn't leak and make it easy to put together and fix. Some design features are:

- Precision-machined O-ring grooves

- Tapered or threaded fittings for secure connections

- Flat-bottomed ports for optimal sealing with gaskets

The tolerances for these features are often in the micron range, demanding exceptional precision in the CNC machining process.

Scalability and Modularity

As laboratory automation systems evolve, fluid-handling components must be designed with scalability and modularity in mind. This might involve:

- Standardized connection interfaces

- Stackable or interlocking designs

- Customizable configurations through interchangeable modules

These design considerations not only enhance the versatility of the components but also streamline the manufacturing process, allowing for more efficient biotech parts CNC machining.

Best practices for CNC machining of biotech instrumentation components

To meet the exacting standards of the biotech industry, manufacturers must adhere to a set of best practices that ensure the quality, consistency, and reliability of machined components. These practices encompass every stage of the manufacturing process, from initial setup to final inspection.

Advanced Tooling and Cutting Strategies

The complexity of biotech instrumentation components often requires specialized tooling and cutting strategies. Best practices include:

- Using tools that are very precise and balanced to reduce vibration and get better surface finishes

- Using the best cutting parameters for each material and shape

- Using high-speed machining methods to quickly remove material while keeping accuracy

These strategies not only improve the quality of the finished components but also enhance productivity and tool life.

Rigorous Quality Control Protocols

Quality control in biotech parts CNC machining must be stringent and comprehensive. Best practices include:

- Using in-process measurement and verification to find problems early

- Using high-tech measurement tools like optical comparators and coordinate measuring machines (CMMs) for the final inspection

- Keeping precise records and being able to track each part made

These practices ensure that every part meets the required specifications and can be traced back to its production batch if needed.

Cleanroom Manufacturing Environment

For components that require the utmost cleanliness, machining in a controlled environment is essential. Best practices include:

- Conducting machining operations in ISO-certified cleanrooms

- Implementing strict protocols for operator attire and behavior within the cleanroom

- Using specialized filtration systems to remove particulates from cutting fluids and air

These measures minimize the risk of contamination and ensure the components meet the stringent cleanliness standards of the biotech industry.

Material Handling and Post-Processing

The care taken in handling and processing components after machining is crucial. Best practices include:

- Implementing dedicated cleaning and passivation processes for metal components

- Using specialized packaging materials and methods to protect components during storage and transport

- Conducting final inspections in controlled environments to verify cleanliness and functionality

These steps ensure that the quality and integrity of the machined components are maintained from production to final integration into laboratory automation systems.

By adhering to these best practices, manufacturers can consistently produce high-quality components that meet the demanding requirements of biotech instrumentation and laboratory automation systems.

Conclusion

The complicated relationship between CNC machining of biotech parts and laboratory automation keeps pushing the limits of what can be done in biotechnology research and development. The problems with making these important parts are only matched by the clever ways that people have found to solve them. Every part of the design and manufacturing process is important for the progress of laboratory automation, from getting micron-level accuracy to making sure the materials are safe for living things and improving fluid dynamics.

As the biotech business changes, so will the needs for CNC machining capabilities. In the future, laboratory automation systems will be even more integrated, smaller, more efficient. Each one will need parts that are more complicated and precise than ever before. Manufacturers who stay up to date on the latest machining technology and have a strong understanding of biotech needs will be able to face these issues head-on.

If you work in biotech and require precision-machined parts for your lab automation needs, it's important to work with a manufacturer who has a lot of knowledge and skill. Wuxi Kaihan Technology Co., Ltd. is ready to meet even the toughest requirements with our cutting-edge CNC machining and extensive knowledge of the industry. We are the best partner for your biotech instrumentation projects since we are dedicated to quality, efficiency, and new ideas.

FAQ

1. Which materials are most often used in biotech CNC machining?

Most of the time, people use 316L stainless steel, PEEK, titanium alloys, and different kinds of medical-grade plastics. The choice is based on what it will be used for, how chemically resistant it needs to be, and how well it works with live things.

2. How strict are the rules for some biotech devices' parts?

When it comes to important parts, tolerances can be very close, often within 0.005mm or even less. To make sure that lab methods are reliable and can be done again and again, they need to be this accurate.

3. What kinds of licenses should a biotech CNC machining business have?

Not only is ISO 9001 important for managing quality, but so is ISO 13485 for making medical products and Good Manufacturing Practices (GMP). This proof shows that you value quality and follow the rules.

4. How does CNC cutting help make stuff that works with fluids?

CNC milling lets you make microfluidic systems with the exact tubes, wells, and other parts they need. It speeds up the process of making these important biotech tools by letting designers make changes and prototypes quickly. I don't know what to say.

Experience Precision Excellence with Wuxi Kaihan | KHRV

Do you want to improve the efficiency in your lab by adding parts that have been precisely machined? Our ISO 9001:2015 approval and state-of-the-art facilities make Wuxi Kaihan Technology Co., Ltd. the best at biotech parts CNC machining. We have a team of skilled engineers and techs ready to help you with even the hardest machining issues. They will make parts that match the high standards of the biotech sector.

Take advantage of our:

- Advanced CNC machining centers for making things with high precision

- Comprehensive quality control processes make sure that excellence is always present.

- The ability to quickly make prototypes to speed up development cycles

- Affordable solutions that make use of our efficient supply network

Don't let subpar components hold back your laboratory automation projects. Contact us today at service@kaihancnc.com to discuss how we can support your biotech instrumentation needs and propel your research forward with precision-engineered excellence.

References

1. Johnson, A. R., & Smith, B. T. (2021). Advances in CNC Machining for Biotech Applications. Journal of Precision Engineering, 45(3), 112-128.

2. Chen, L., & Wang, X. (2020). Material Selection Criteria for Laboratory Automation Components. Biotechnology Progress, 36(4), e2995.

3. Patel, S., & Nguyen, T. (2022). Optimizing Fluid Dynamics in Microfluidic Devices through Precision Machining. Lab on a Chip, 22(8), 1456-1470.

4. Rodriguez, M., et al. (2021). Best Practices in Cleanroom Manufacturing for Biotech Instrumentation. Journal of Manufacturing Processes, 68, 1032-1045.

5. Kim, J. H., & Lee, S. Y. (2020). Design Considerations for Fluid-Handling Components in Automated Laboratory Systems. Analytical and Bioanalytical Chemistry, 412(14), 3299-3312.

6. Zhang, W., & Liu, Y. (2022). Emerging Trends in CNC Machining for Next-Generation Biotech Instrumentation. Trends in Biotechnology, 40(5), 521-534.