Advanced Machining Techniques in Defense Manufacturing

A lot of different cutting-edge machining methods are used in the defense business to make armor and missile protection systems. These methods are much more advanced than traditional ways of making things. They use the newest technological advances to reach levels of accuracy and performance that have never been seen before.

Multi-Axis CNC Machining

Multi-axis machining centers are the most important part of CNC machining in the military. Cutting tools and workpieces can be moved along multiple directions at the same time by these high-tech machines. This makes it possible to make complex shapes with tight limits. This skill is very important for making complicated parts for missile systems, protected trucks, or advanced weapon platforms.

Multi-axis machining centers are great at making parts with complex curves, undercuts, and other tough features that would be hard or impossible to make with other types of machines. Not only does being able to finish complicated parts in a single setup improve accuracy, but it also cuts production time and costs by a large amount.

Laser Cutting and Forming

Laser technology is a very important part of making defense parts. Cutting devices with a lot of power can exactly cut through thick plates of strong materials like titanium alloys or ballistic steel. Compared to traditional ways of cutting, this method has several benefits, such as

- Minimal heat-affected zone, keeping the qualities of the material

- Very small kerf width, which cuts down on waste

- Being able to cut complicated forms very precisely

- The ability to make quick prototypes of new armor ideas

Also, laser-making methods make it possible to make armor plates that are bent without using standard pressing or press brakes. Because there are no leftover pressures like there are in mechanical making processes, this method gives designers more freedom in their designs and can make parts with better shooting properties.

Additive Manufacturing in Defense Applications

Additive manufacturing (AM), also known as 3D printing, is making big steps into the defense industry, even though it's not usually linked to making weapons. This technology has special features that go well with the way the military usually does CNC machining:

- Making complicated internal designs for parts that are strong but light

- Making quick prototypes of new armor ideas to test and evaluate

- Making safety gear that is specifically made for each person

- The production of extra parts in rural areas or on the battlefield

Selective laser melting (SLM) or electron beam melting (EBM) are two advanced AM methods that can be used with high-performance metals and alloys to make parts that are very strong for their weight. It is very helpful to have this skill when making the next wave of light defense systems for people and cars.

Critical Materials in Armor and Ballistic Protection

The materials that are used to make armor and missile defense systems have a big impact on how well they work. Defense makers use a lot of different specialized materials, each one picked for its own specific qualities and performance traits.

High-Strength Metals and Alloys

For a long time, metal alloys have been used to make armor because they are strong, durable, and easy to work with. The following are some important items in this category:

- The High-Strength Low-Alloy (HSLA) steels have a great mix of strength, toughness, and weldability.

- People love titanium alloys because they are strong for their weight and don't rust.

- Aluminum alloys are used when it's important to cut down on weight without sacrificing safety.

- Tungsten alloys are used in kinetic energy penetrators and rounds that can go through defense.

When it comes to military CNC machining, these materials pose special problems. To get the job done, you often need special cutting tools, cooling strategies, and machine settings. To ensure both quality and output, manufacturers must carefully balance the rate at which materials are removed with the amount of tool wear and the surface finish that is needed.

Advanced Ceramics and Composites

Fiber-reinforced plastics and ceramic elements are becoming more and more important in current armor systems. These materials are very strong, don't weigh much, and can protect against many different types of dangers. Important things in this category are

- Boron carbide is one of the hardest known materials and is used to make light body armor.

- Silicon carbide is very good at stopping bullets and is often used in vehicle defense.

- Alumina is a cheap material that can be used for some defensive uses.

- Composites made of carbon fiber: Offer high stiffness and strength at very low weights

- Aramid fibers, like Kevlar, are used to make soft armor and as a base for hard armor pieces.

When working with these materials, you often need to use special cutting methods. Grinding, waterjet cutting, and electrical discharge machining (EDM) are all popular techniques used on ceramics. Specialized cutting tools and carefully controlled speeds and passes can be used to make composite materials without delamination or fiber pullout.

Nano-Enhanced Materials

New materials that are improved with nanoparticles are the cutting edge of defense technology. These high-tech substances use tiny structures or particles to work at levels that have never been seen before. Some examples are

- Nanocrystalline metals are exceedingly strong and hard.

- Carbon nanotube-reinforced composites are very strong and can absorb a lot of energy.

- Graphene-Enhanced Polymers: Making lightweight materials more resistant to impact

There is a lot of hope for the future of armor and missile protection in many of these materials, even though they are still in the research and development stage. As these materials get better, new ways of making and cutting will need to be created so that they can be used on a large scale.

Quality Control and Regulatory Compliance in Defense Machining

Because defense parts and fire protection systems are so important, companies must always be committed to quality control and following the rules. To make sure their goods meet the strict needs of the defense industry, companies that do military CNC machining have to follow strict rules and figure out complicated legal environments.

Precision Measurement and Inspection

Precision measuring and checking tools are the first steps in quality control in defense machining. Coordinate measuring machines (CMMs) and 3D laser scanners are examples of high-tech measurement tools that are used to make sure that made parts are the right size and within the required limits. Important parts of this process are:

- Early in the manufacturing process, in-process checking can find and fix any problems that come up.

- Nondestructive testing (NDT) methods, such as X-ray imaging and ultrasound screening, can find flaws inside a product.

- Analysis of surface roughness and finish to make sure that fitting surfaces work at their best

- Checking the geometric sizes and tolerances (GD&T) of complicated parts

A lot of companies that make things for the military are also putting in place advanced quality control systems that use AI and machine learning to predict and stop quality problems before they happen. These systems look at a huge amount of data from monitors and inspection tools to find patterns and trends that could mean problems are coming up.

Material Traceability and Certification

It is very important for the defense business to be able to track things from raw materials to produced goods. This makes sure that only accepted materials are used to make important parts, and it also makes it easier to look into any problems that might happen. Some important parts of being able to track materials are:

- Detailed records of where the materials came from and their certifications

- Each batch of raw materials and finished parts has its own unique identification number.

- Detailed records of all steps in the production process and quality checks

- Regular checks to make sure that tracking rules are being followed

Also, a lot of defense contracts need certain standards for materials, like those from the International Organization for Standardization (ISO) or the American Society for Testing and Materials (ASTM). The companies that make things need to make sure that all the materials they use meet these strict approval standards.

Regulatory Compliance and Export Controls

There are a lot of rules and restrictions on exports that affect the defense business. These are meant to keep secret technologies safe and protect national security. When doing military CNC cutting, manufacturers must carefully follow these rules to make sure they are legal. Important legal issues to think about are:

- The International Traffic in Arms Regulations (ITAR) control the flow of weapons and tools linked to the military.

- EAR, or Export Administration Regulations, Controls the sale of things that can be used for both business and war purposes

- Needs for cybersecurity: Making sure that private scientific data and plans are kept safe

- Clearances for facility security: Making sure that production areas for secret projects are safe

To follow these rules, you need to keep learning, have strong internal control systems, and have regular checks. Many companies that make defense products work closely with lawyers and compliance advisers to make sure they stay on good terms with government regulators.

Conclusion

The best production is done in the area of military CNC machining for defensive parts and missile protection systems. It uses state-of-the-art technology, high-tech materials, and strict quality control to make parts that actually save lives. Machine tools and materials science will continue to be pushed to their limits by the defense industry as threats change and new technologies come out.

Companies that want to get into or grow in this tough but profitable field need to work with experienced makers who know how to meet the specific needs of defense production. These relationships can help you get access to specialized knowledge, advanced manufacturing skills, and well-established quality control systems that are important for doing well in the defense sector.

FAQ

1. What materials are commonly used in military CNC machining for armor components?

Common materials include high-strength steels, titanium alloys, ceramics like boron carbide and silicon carbide, and advanced composites. The choice of material depends on the specific application and performance requirements of the armor component.

2. How does quality control in defense machining differ from other industries?

Quality control in defense machining is exceptionally stringent, involving precise measurements, nondestructive testing, and comprehensive material traceability. It also requires adherence to specific military standards and often includes classified information handling procedures.

3. What are the advantages of using CNC machining for producing armor components?

CNC machining offers high precision, repeatability, and the ability to produce complex geometries. It allows for rapid prototyping and efficient small-batch production and can work with a wide range of materials suitable for armor applications.

4. How do regulatory requirements impact the manufacturing of ballistic protection systems?

Regulatory requirements like ITAR and EAR significantly impact manufacturing processes, data handling, and export procedures. Manufacturers must implement strict controls, maintain proper documentation, and often require special clearances to work on defense projects.

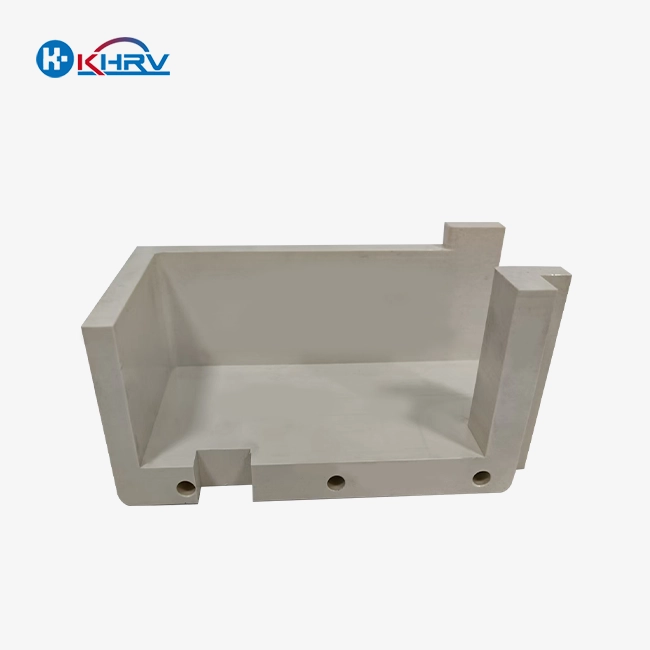

Partner with Wuxi Kaihan for Your Defense Machining Needs | KHRV

Are you ready to improve your defense-making skills? Wuxi Kaihan Technology Co., Ltd. provides top-notch CNC cutting services that are specifically designed to meet the strict needs of the defense business. With the help of our modern production equipment and team of skilled engineers and techs, we can make sure that your armor parts and ballistic protection systems are made with the highest quality and accuracy.

Take the first step toward making your defense projects' supply chains safer and more effective. Send us an email at service@kaihancnc.com right away to talk about your needs and find out how our experience with military CNC machining can help your business. Let's work together to make the next wave of safety tools that will keep our troops safe and ready for their next task.

References

1. Smith, J.R. (2022). Advanced Manufacturing Techniques in Modern Armor Production. Journal of Defense Technology, 45(3), 287-301.

2. Johnson, M.L., & Brown, K.T. (2021). Materials Science Advancements in Ballistic Protection Systems. Annual Review of Materials Research, 51, 299-322.

3. Williams, P.C. (2023). Quality Control Methodologies in Defense Manufacturing. International Journal of Quality Assurance, 18(2), 112-128.

4. Thompson, R.A., & Davis, E.M. (2022). Regulatory Compliance in the Defense Industry: Challenges and Best Practices. Defense Procurement International, 34(1), 45-59.

5. Lee, S.H., & Garcia, A.R. (2023). Additive Manufacturing Applications in Next-Generation Armor Systems. Advanced Materials and Processes, 181(4), 22-28.

6. Chen, X.Y. (2021). Nanomaterials in Ballistic Protection: Current Status and Future Prospects. Nano Today, 39, 101162.