Materials and quality criteria for aerospace CNC machining parts

The selection of materials for aerospace CNC machining parts is a critical process that demands meticulous attention to detail. Space-grade materials must exhibit exceptional properties to withstand extreme temperatures, radiation, and the vacuum of space. Commonly used materials include:

High-performance alloys

Titanium combinations, such as Ti-6Al-4V, are prized for their tall strength-to-weight proportion and erosion resistance. Inconel superalloys, known for their warm resistance and strength, are frequently utilized in rocket motor components. Aluminum amalgams, especially the 7000 series, offer great quality and malleability, making them perfect for auxiliary components.

Specialized polymers and composites

Advanced polymers like Look (Polyether Ether Ketone) and composite materials fortified with carbon or glass strands are progressively utilized for their lightweight properties and thermal stability. These materials regularly discover applications in obsequious structures and payload components.

Quality criteria for space-grade components

The quality standards for aerospace parts are among the most stringent in any industry. Key criteria include:

- Ultra-high precision tolerances, often in the micron range

- Exceptional surface finish to minimize friction and wear

- Zero contamination to prevent outgassing in space

- Rigorous non-destructive testing (NDT) to ensure structural integrity

- Full material traceability and documentation

These demanding guidelines guarantee that each component can perform dependably in the unforgiving environment of space, where failure is not an option.

CNC components for the space industry: materials, machining, and certification

The production of orbital components and satellite parts through CNC machining involves a complex interplay of advanced materials, precision manufacturing techniques, and rigorous certification processes.

Advanced machining techniques

CNC machining for space applications often employs cutting-edge techniques such as:

- 5-axis machining for complex geometries

- Cryogenic machining to maintain material integrity

- Electrical Discharge Machining (EDM) for intricate features

- Additive manufacturing combined with CNC for hybrid parts

These strategies permit the creation of components with exceptional precision and complexity, essential for the demanding requirements of space missions.

Material-specific machining considerations

Different aerospace materials require specialized machining approaches:

- Titanium alloys often necessitate slower cutting speeds and copious cooling to prevent work hardening

- Aluminum alloys can be machined at high speeds, but require careful chip management

- Composite materials demand specialized tooling and dust extraction systems

Understanding these material-specific necessities is vital for accomplishing the desired accuracy and surface quality in aviation components.

Certification and quality assurance

The certification process for space-grade components is rigorous and multifaceted:

- AS9100 certification is typically required for aerospace manufacturers

- NADCAP accreditation for special processes like heat treatment or surface finishing

- Material certifications and lot traceability for all raw materials

- Extensive documentation and quality control records

- First Article Inspection (FAI) reports for new or modified parts

These certifications ensure that every component meets the exacting standards required for space applications, from launch vehicles to satellite systems.

Precision manufacturing of aerospace CNC components: standards and best practices

The fabrication of aviation CNC components for orbital applications requires adherence to the most elevated benchmarks and execution of industry-leading best practices. This guarantees that each portion can withstand the extraordinary conditions of space while performing its basic work reliably.

Industry standards for aerospace manufacturing

Key standards governing the production of space-grade components include:

- ISO 9001 and AS9100 for quality management systems

- ASTM E3022 for additive manufacturing in aerospace applications

- MIL-STD-810 for environmental engineering considerations and laboratory tests

- ECSS-Q-ST-70-71C for materials, mechanical parts, and processes for space applications

Adherence to these measures guarantees consistency, unwavering quality, and interoperability of components over distinctive space frameworks and missions.

Best practices in precision aerospace machining

To achieve the ultra-high precision required for satellite parts and other space components, manufacturers employ a range of best practices:

- Implementation of climate-controlled manufacturing environments

- Use of high-precision metrology equipment for in-process and final inspection

- Development of custom fixturing and tooling for complex geometries

- Continuous monitoring and adjustment of machining parameters

- Implementation of statistical process control (SPC) for quality assurance

These hones offer assistance to keep up consistency and precision throughout the fabrication prepare, guaranteeing that each component meets the demanding details required for space applications.

Emerging technologies in aerospace manufacturing

The space industry continually pushes the boundaries of manufacturing technology. Some emerging trends include:

- Integration of artificial intelligence for optimizing machining parameters

- Use of digital twins for virtual testing and validation

- Implementation of in-situ monitoring systems for real-time quality control

- Development of novel materials and alloys specifically for space applications

These headways are driving enhancements in component execution, unwavering quality, and cost-effectiveness, empowering more advanced space missions and applications.

Conclusion

The machining of components for the space industry speaks to the apex of accurate fabrication. From the cautious determination of progressed materials to the usage of thorough quality control measures, each step in the process is crucial to ensuring the success and security of space missions. As we proceed to thrust the boundaries of space investigation, the role of high-precision CNC machining in making solid, high-performance orbital components and faying parts will in it were develop in importance.

For companies included in the aviation and obsequious businesses, joining forces with a talented and experienced CNC machining supplier is fundamental. Wuxi Kaihan Innovation Co., Ltd. offers state-of-the-art CNC machining services custom-fitted to the demanding needs of the space industry. With our progressed hardware, including 10 CNC machining centers and 6 CNC machines, we can provide high-precision components that meet or surpass industry benchmarks. Our ISO9001:2005 certification and commitment to quality guarantee that each portion we deliver is space-ready. Whether you require custom obsequious components, precision-engineered orbital parts, or specialized aviation installations, our group of specialists is prepared to support your mission-critical projects.

Don't compromise on quality when it comes to space-grade components. Contact Wuxi Kaihan Innovation Co., Ltd. nowadays to talk about your aviation CNC machining needs and encounter the distinction that accuracy, unwavering quality, and ability can make in your space industry projects.

FAQ

1. What are the most common materials used in aerospace CNC machining?

Aerospace quality measures are essentially more rigid than those in most other businesses. They require ultra-high accuracy resiliences (regularly in the micron extend), uncommon surface wraps up, zero defilement, and comprehensive non-destructive testing. Moreover, full fabric traceability and broad documentation are obligatory, guaranteeing that each component's history can be confirmed from crude fabric to the last installation.

2. How do quality standards for aerospace components differ from other industries?

Aerospace quality measures are essentially more rigid than those in most other businesses. They require ultra-high accuracy resiliences (regularly in the micron extend), uncommon surface wraps up, zero defilement, and comprehensive non-destructive testing. Moreover, full fabric traceability and broad documentation are obligatory, guaranteeing that each component's history can be confirmed from crude fabric to the last installation.

3. What certifications are required for manufacturing space-grade components?

Key certifications for fabricating space-grade components incorporate AS9100 for quality administration frameworks particular to the aviation industry, NADCAP accreditation for uncommon forms, and compliance with measures like ASTM E3022 for added substance fabricating in aviation. Producers may also be required to meet particular necessities set by space organizations or prime contractors, such as NASA or ESA specifications.

4. How is precision maintained in the manufacturing of orbital components?

Precision in fabricating orbital components is kept up through a combination of progressed technologies and thorough forms. This incorporates utilizing climate-controlled fabricating situations, high-precision metrology hardware for persistent estimation, custom fixturing and tooling, and real-time observing of machining parameters. Furthermore, factual handle control (SPC) and in-situ checking frameworks are utilized to guarantee reliable quality through the production process.

Ready to Launch Your Space Industry Projects with Precision CNC Machining | KHRV

Are you looking for a solid accomplice to fabricate high-precision components for your space industry ventures? Wuxi Kaihan Innovation Co., Ltd. is your go-to arrangement for aerospace-grade CNC machining. With our state-of-the-art offices, ISO9001:2005 certification, and a group of experienced engineers, we're prepared to handle your most demanding orbital component and lackey portion requirements.

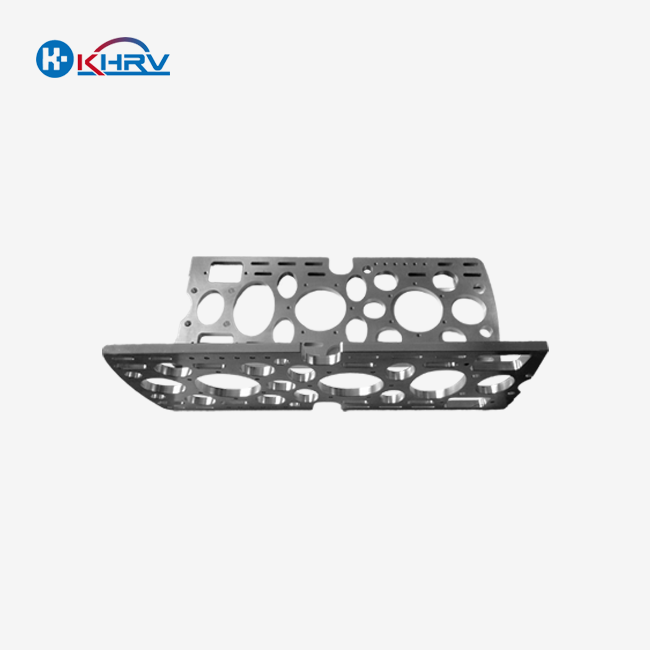

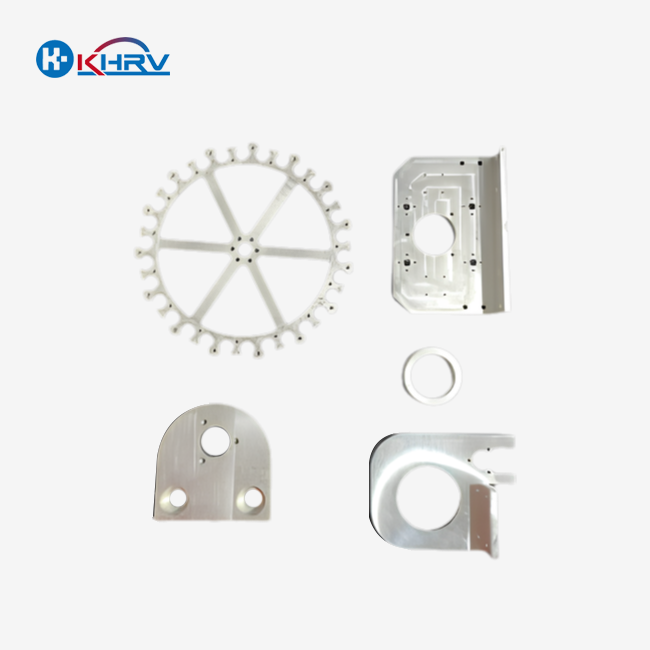

Take advantage of our competitive estimating, fast turnaround times, and faithful commitment to quality. Our Aerospace CNC Machining Parts are manufactured with precision and reliability to meet the most demanding industry standards, ensuring superior performance and durability in every application. Whether you require models or large-scale generation runs, our adaptable fabrication capabilities can oblige your needs. Do not let subpar components compromise your space missions – select Wuxi Kaihan for accuracy, unwavering quality, and fabulousness in aviation CNC machining.

Ready to elevate your space industry projects? Contact us today at service@kaihancnc.com to discuss your specific requirements and discover how we can support your mission to the stars. Let's work together to push the boundaries of space exploration with cutting-edge CNC-machined components.

References

1. Smith, J. A. (2022). Advanced Materials for Aerospace Applications: Properties and Manufacturing Processes. Journal of Aerospace Engineering, 35(2), 145-160.

2. Johnson, R. B., & Thompson, L. M. (2021). Precision Machining Techniques for Satellite Components: A Comprehensive Review. International Journal of Aerospace Manufacturing Technology, 18(4), 412-428.

3. Aerospace Industries Association. (2023). Quality Management Systems - Requirements for Aviation, Space, and Defense Organizations (AS9100 Rev. E). Washington, DC: AIA Publications.

4. European Cooperation for Space Standardization. (2022). Space Product Assurance: Materials, Mechanical Parts and Processes (ECSS-Q-ST-70-71C). Noordwijk, Netherlands: ESA Requirements and Standards Division.

5. NASA. (2021). NASA Technical Standard: Environmental Engineering Considerations and Laboratory Tests (NASA-STD-7002B). Washington, DC: NASA Technical Standards Program.

6. International Organization for Standardization. (2023). Space Systems - Definition of the Technology Readiness Levels (TRLs) and Their Criteria of Assessment (ISO 16290:2023). Geneva, Switzerland: ISO.