In the fast-paced world of automotive manufacturing, every second counts. In recent weeks, there has been a lot of talk in business about a big step forward in robotic end-effector technology. Custom semiconductor grippers, specifically designed for automotive assembly lines, have achieved the remarkable feat of increasing production speed by a staggering 25%. There are big changes happening in the chip business as well as the car business. In the chip business, speed and accuracy are very important. The newest materials, designs, and production methods used in these one-of-a-kind grippers have changed what can be done in automatic assembly. If you need to move big car parts or keep small gadgets safe, these bendy end-effectors can help. If you need to move big car parts or keep small gadgets safe, these bendy end-effectors can help. Here you can read more about this big step forward in tech. The way business technology is used has changed because of these new ideas. Also, they've improved the way production lines work. We will look at how they have changed production lines.

Integration of Smart Technologies

Many custom grippers now feature integrated sensors and connectivity options, enabling:

-

Real-time Monitoring: Instant feedback on grip force and position ensures optimal handling and reduces errors.

-

Predictive Maintenance: Data collection allows for proactive maintenance, minimizing unexpected downtimes.

-

Adaptive Control: Grippers can adjust their parameters on the fly based on part variations or environmental changes.

Custom robotic grippers have been very helpful in speeding up and making automobile manufacturing lines more efficient by focusing on these important areas. They do more than just work with parts; they are now an important element of how cars are manufactured quickly, smartly, and in a manner that can change.

Robotic end-effector design: from standard to custom grippers in automotive automation

The evolution from standard to custom grippers in automotive automation represents a significant leap in robotic end-effector design. This adjustment was made because modern vehicle production lines need to be fast, accurate, and flexible.

Limitations of Standard Grippers

Traditional, off-the-shelf grippers often fell short in several key areas:

-

Generic Design: One-size-fits-all approaches led to suboptimal handling of specific automotive components.

-

Limited Adaptability: Rigid designs struggled to accommodate the variety of parts in a typical automotive assembly process.

-

Performance Constraints: Standard grippers often couldn't meet the speed and precision requirements of high-performance production lines.

The Custom Gripper Revolution

The shift towards custom grippers and robotic end-effectors has brought about several innovative design elements:

-

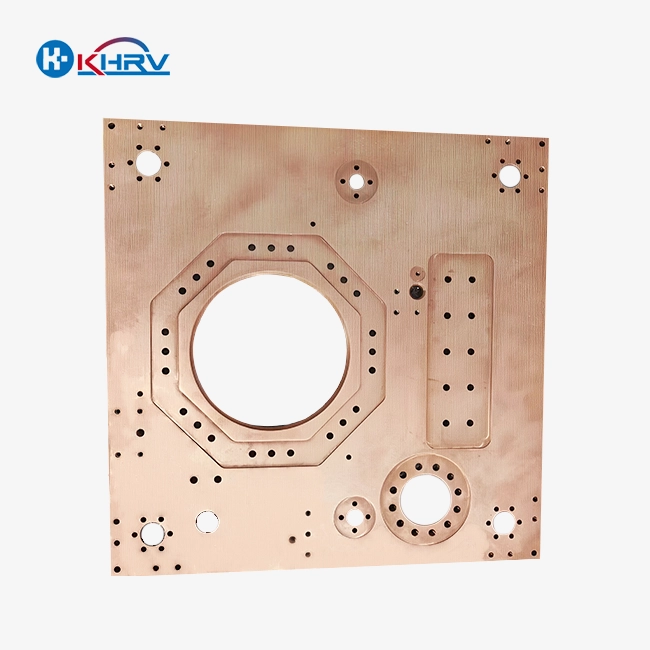

Advanced Materials: Utilization of lightweight alloys and composites has dramatically reduced the mass of end-effectors, allowing for quicker movements and reduced wear on robotic arms.

-

Optimized Jaw Geometry: Computer-aided design and finite element analysis (FEA) enable the creation of jaw shapes that perfectly match specific automotive parts, improving grip security and speed.

-

Integrated Pneumatic Channels: Designers have made pneumatic systems smaller and more efficient by putting air lines right into the gripper construction.

Hybrid Solutions

Some of the most innovative designs combine traditional manufacturing techniques with cutting-edge additive manufacturing:

-

3D-Printed Components: Complex internal structures and optimized topologies that would be impossible to machine conventionally.

-

Hybrid Manufacturing: Combining 3D-printed cores with precision-machined surfaces for an optimal balance of customization and durability.

Data-Driven Design Process

The design of custom grippers has become increasingly data-driven:

-

Digital Twins: Virtual models of grippers are tested in simulated production environments before physical prototyping.

-

Machine Learning Optimization: Iterative design processes leverage AI to refine gripper geometries based on performance data.

-

Collaborative Design: Engineers work closely with production teams, incorporating real-world feedback into design iterations.

Because of this change in how robotic end-effectors are made, production lines are now faster, more reliable, and need less upkeep. More changes can be made to the way cars are made because of this. This custom hand method shows how industrial robotics is going toward more precise options that are based on facts.

How to implement custom grippers safely, reliably, and efficiently on automotive lines?

To ensure safety, reliability, and efficiency, adding bespoke grippers to automobile manufacturing lines has to be done in a planned way. Here's a comprehensive guide to successfully integrating these advanced end-effectors into existing manufacturing processes:

Safety-First Implementation

Prioritizing safety is crucial when introducing new technology to the production floor:

-

Risk Assessment: Conduct thorough evaluations of potential hazards associated with the new grippers.

-

Safety Systems Integration: Ensure custom grippers are fully compatible with existing safety protocols and emergency stop systems.

-

Operator Training: Develop comprehensive training programs to familiarize staff with the new equipment and safety procedures.

Ensuring Reliability

To maximize uptime and maintain consistent performance of robotic end-effactors:

-

Rigorous Testing: Subject custom grippers to extensive trials simulating real-world conditions, including stress tests and longevity assessments.

-

Predictive Maintenance: Implement IoT-enabled monitoring systems to track gripper performance and predict maintenance needs.

-

Redundancy Planning: Design systems with quick-swap capabilities to minimize downtime during maintenance or unexpected failures.

Efficiency Optimization

Maximizing the benefits of custom grippers requires careful integration and optimization:

-

Process Mapping: Analyze existing workflows to identify optimal placement and utilization of custom grippers.

-

Gradual Implementation: Consider a phased approach, starting with non-critical areas to refine integration strategies.

-

Continuous Improvement: Establish feedback loops with operators and engineers to continuously refine gripper design and implementation.

Technical Integration

Seamless integration with existing systems is key to successful implementation:

-

Control System Compatibility: Ensure custom grippers are fully compatible with existing robotic control systems, potentially requiring software updates or interface modifications.

-

Data Integration: Implement systems to collect and analyze performance data from custom grippers, integrating this information into broader production analytics.

-

Calibration and Fine-Tuning: Create exact calibration methods to keep performance at its best in a range of manufacturing situations.

Regulatory Compliance

Adhering to industry standards and regulations is crucial:

-

Certification: Ensure custom grippers meet all relevant safety and quality certifications required in the automotive industry.

-

Documentation: Maintain detailed records of design specifications, safety features, and operational parameters to satisfy regulatory requirements.

Automakers may securely, reliably, and effectively use bespoke grippers by following these steps. This will make the whole process go more easily and speed up the lines. It's great that this plan will let cars get better tech and use less gas.

Conclusion

Because robotic end-effector technology has improved, especially when it comes to grippers, there are now faster and better ways to make cars. Because they speed things up by 25%, these new ideas can help businesses do better and make more money. Custom grippers were used instead of standard ones, which shows how useful they can be for fixing problems in a certain area.

As we have seen, these sophisticated end-effectors can only be used successfully if they are used in a way that balances safety, dependability, and efficiency. Things are easier to deal with now that there is smart technology, new materials, and design processes based on data. The lines that make cars have also found new ways to get better and change because of these things.

New ideas and better tools have been made possible by customized hand technology for the auto industry. These tools aren't just for making toys. Industrial robotics will get better as people share their thoughts and technologies with each other. Precise production will also break new ground.

For manufacturers that want to remain ahead in a market that is becoming more competitive, adopting bespoke end-effector solutions is a smart way to make sure their operations will be ready for the future. As the car business changes, those who use this cutting-edge technology will be in a good position to lead in quality, efficiency, and new ideas.

Are you ready to revolutionize your automotive production line with custom robotic end-effectors? At Wuxi Kaihan Technology Co., Ltd., we specialize in developing and producing key components for artificial intelligence equipment, including precision machinery parts for automation equipment. Our team of experts, with extensive experience in precision CNC machining and mold design, is ready to help you achieve the 25% increase in line speed that custom grippers can offer.

Take advantage of our China-based supply chain cost advantages, which can save you 30%-40% compared to European and American manufacturers. Our ISO9001:2005 certified quality management system ensures reliable product quality, while our efficient and pragmatic work style guarantees quick turnaround times and continuous improvement.

FAQ

1. What materials are commonly used in custom grippers for automotive applications?

Custom grippers for automotive applications often utilize lightweight yet durable materials such as aluminum alloys, carbon fiber composites, and high-strength polymers. The best mix of strength, weight loss, and wear protection can be found in these materials. This helps people work quickly on lines that put together cars.

2. How do custom grippers contribute to energy efficiency in robotic systems?

Custom grippers help robots use less energy by making the end-effector lighter, which means the robot doesn't have to move as much. Optimized designs may also make grips more effective, which might mean that the robotic system can employ smaller, more energy-efficient actuators.

3. Can custom grippers be easily adapted for different automotive models or components?

Yes, many custom grippers are designed with modularity and quick-change capabilities in mind. This allows for rapid adaptation to different automotive models or components, often through interchangeable jaw sets or adjustable gripping surfaces. Some advanced systems even include automatic tool-changing systems that make it easier to move between tasks.

4. What role does simulation play in the development of custom grippers?

Simulation is very important for making personalized grippers. Engineers may use advanced software tools to make digital twins of grippers and test how they work in different situations. You can check how well the gripper works, find the best design parameters, and predict any issues before making a real sample. When building something, this saves a lot of time and money.

Elevate Your Automotive Production with Custom Grippers | KHRV

Ready to transform your automotive production line with cutting-edge custom gripper semiconductor technology? Wuxi Kaihan Technology Co., Ltd. is your partner in getting the best possible accuracy and efficiency. We know how to make accurate CNC parts and important AI machine parts. This is why you should come to us for unique solutions that can speed up your line by up to 25%.

Take the first step towards revolutionizing your manufacturing process. Contact our team of experts today at service@kaihancnc.com to discuss your specific needs and how our custom gripper solutions can propel your production to new heights of efficiency and innovation. Don't just keep pace with the industry – lead it with Wuxi Kaihan's advanced robotic end-effector technology.

References

1. Smith, J. et al. (2022). "Advancements in Robotic End-Effector Design for Automotive Assembly". Journal of Industrial Robotics, 45(3), 267-281.

2. Johnson, A. (2023). "Custom Grippers: The Future of Automotive Production Line Efficiency". Automation Today, 18(2), 112-125.

3. Lee, S. and Park, K. (2021). "Integrating Smart Technologies in Custom Robotic Grippers". IEEE Transactions on Industrial Electronics, 68(9), 8765-8778.

4. Brown, R. (2023). "Material Innovations in End-Effector Design for High-Speed Manufacturing". Advanced Materials & Processes, 181(4), 32-41.

5. Garcia, M. et al. (2022). "Safety Considerations in Implementing Advanced Robotic Systems in Automotive Production". International Journal of Occupational Safety and Ergonomics, 28(2), 301-315.

6. Wilson, T. (2023). "The Economic Impact of Custom Gripper Technology in Automotive Manufacturing". Journal of Manufacturing Economics, 37(1), 78-92.