Principles of Damped Machined Components

At the core of damped machined components lies the principle of energy dissipation. These components are crafted to convert mechanical vibration energy into heat through internal friction or deformation of viscoelastic materials. The frequency of the sound drops, and it can't move through the system. This "damps" the sound.

Key features of damped machined components include:

-

Integrated Damping Materials: Viscoelastic polymers or specialized alloys are often incorporated into the component's structure.

-

Tuned Mass Dampers: Some components utilize small, tuned masses to counteract specific frequencies of vibration.

-

Constrained Layer Damping: Layers of damping material are sandwiched between stiff layers to maximize energy dissipation.

Mechanisms of Noise and Vibration Reduction

Damped machined components and precision instruments reduce noise and vibration through several mechanisms:

-

Energy Absorption: The damping materials within the component absorb vibrational energy, preventing it from being transmitted to other parts of the system.

-

Frequency Shifting: By altering the natural frequency of the system, damped components can shift problematic vibrations away from sensitive operational ranges.

-

Amplitude Reduction: The damping effect decreases the amplitude of vibrations, minimizing their impact on precision and accuracy.

These parts work together to make the place where precision instruments are used more stable. They work better and last longer this way.

Design Techniques for Integrating Vibration Damping into CNC Machined Parts

When designing and choosing materials for CNC machined components that need vibration dampening, you need to be careful. Engineers need to think about the individual vibration problems that each application has and make the damping solution fit those problems. The objective is to make parts that not only do their main job, but also help keep the precise instrument or machine stable.

Material Selection for Damped Components

Choosing the right materials is crucial for effective vibration damping in CNC machined parts. Some key considerations include:

-

Viscoelastic Polymers: These materials offer excellent damping properties and can be integrated into components through various methods.

-

Metal Matrix Composites: Combining metals with damping particles can create components with both high strength and vibration-absorbing capabilities.

-

Specialized Alloys: Certain metal alloys exhibit inherent damping properties that can be leveraged in precision components.

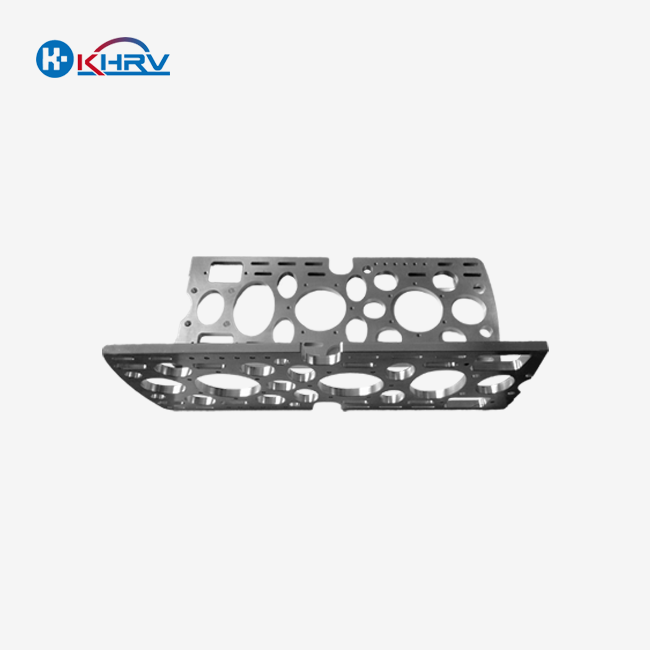

Structural Design for Enhanced Damping

The geometry and structure of CNC machined parts can be optimized to enhance their damping capabilities:

-

Honeycomb Structures: Incorporating internal honeycomb patterns can increase damping while maintaining structural integrity.

-

Constrained Layer Damping: Adding layers of dampening material to parts may make them much better at absorbing vibrations.

-

Tuned Mass Dampers: Integrating small, precisely calibrated masses within the component can target specific problematic frequencies.

Engineers may make CNC machined components that successfully reduce vibrations without sacrificing performance or durability by carefully thinking about both the material qualities and the structural design for vibration damping.

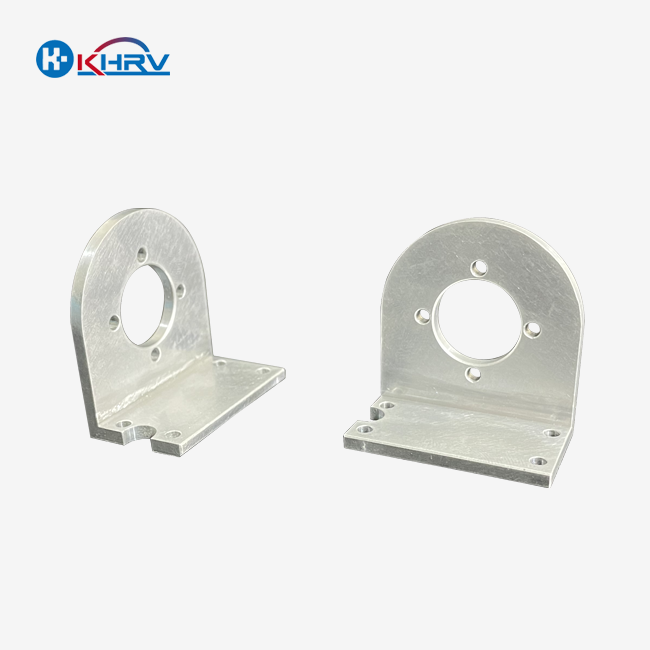

Improving Accuracy and Longevity in Sensitive Equipment like Metrology Tools and Optics

Using damped machined parts in sensitive devices like optical systems and metrology instruments may make them far more accurate and last much longer. These parts assist maintain the accurate alignments and measurements needed for high-performance operations by reducing the effects of vibrations.

Enhancing Measurement Precision in Metrology

In metrology applications, even minute vibrations can lead to measurement errors that compromise the validity of results. Damped machined components and precision instruments contribute to improved accuracy by:

-

Stabilizing Measurement Platforms: Damped components in the base or frame of metrology equipment reduce environmental vibrations.

-

Improving Probe Stability: For contact measurement systems, damped probes can maintain more consistent contact with the measured surface.

-

Enhancing Optical System Performance: In optical metrology, damped components help maintain precise alignment of lenses and sensors.

Extending the Lifespan of Optical Equipment

Optical systems and precision instruments are particularly sensitive to vibrations, which can cause misalignments and damage over time. Damped machined components contribute to the longevity of optical equipment by:

-

Reducing Wear on Precision Components: By minimizing vibration-induced movement, damped parts help prevent premature wear on delicate optical elements.

-

Maintaining Calibration: Stable, vibration-free environments help optical systems maintain their calibration for longer periods, reducing the need for frequent adjustments.

-

Protecting Sensitive Coatings: Many optical components feature specialized coatings that can be damaged by excessive vibration. Parts that are softened help keep these important places safe.

Adding damped machined parts to sensitive equipment not only makes it work better right away, but it also makes it more reliable in the long run and requires less maintenance.

Conclusion

Sharp tools are much less likely to shake when they use parts that have been softened after they have been made. When manufacturers add vibration dampening directly to important parts, their equipment becomes more accurate, stable, and long-lasting. We can make tools that work better and faster from now on by following this method. Now things work better too.

Using damped made parts could give companies that make new energy-producing equipment, robots, high-end CNC machine tools, and medical devices an edge over their competitors. With these parts, you can improve items for less money, keep sensitive equipment in good shape longer, and make it last longer.

At Wuxi Kaihan Technology Co., Ltd., we specialize in the design and manufacture of precision components, including those with advanced vibration damping capabilities. There are people here who can help you make it less likely that your things will shake. Precision CNC cutting and cast creation are two things they know a lot about. Whether you need custom damped components for robotics, metrology tools, or any other precision application, we have the expertise and technology to meet your requirements.

Take advantage of our cost-effective manufacturing solutions, backed by our ISO9001:2011 certified quality management system. We are always open to new ideas and have state-of-the-art CNC machines that we can use to help you make your goods exact and reliable. Contact us today at service@kaihancnc.com to discuss how our damped machined components can solve your vibration challenges and enhance the performance of your precision instruments. Let's work together to push the boundaries of precision and stability in your industry.

References

1. Smith, J. D. (2019). Advanced Vibration Damping Techniques in Precision Machining. Journal of Manufacturing Science and Engineering, 141(8), 081001.

2. Chen, L., & Wang, X. (2020). Integrated Design of Damped Components for High-Precision Instruments. Precision Engineering, 62, 128-142.

3. Takahashi, K., et al. (2018). Novel Viscoelastic Materials for Enhanced Vibration Damping in CNC Machined Parts. Materials & Design, 156, 88-97.

4. Brown, A. R. (2021). Improving Metrology Accuracy Through Advanced Damping Mechanisms. Measurement Science and Technology, 32(6), 064001.

5. Liu, Y., & Zhang, Q. (2020). Longevity Enhancement of Optical Systems Using Damped Structural Components. Optics Express, 28(15), 22103-22118.

6. Johnson, M. E. (2019). Vibration Control in Precision Manufacturing: A Comprehensive Review. International Journal of Machine Tools and Manufacture, 139, 1-23.