Precision mechanical assemblies are the backbone of modern production. They drive innovation in a wide range of fields, from robots to medical devices. To keep up with the changing needs of sophisticated industrial applications, these complex systems need to be extremely accurate, dependable, and high-performing. As we move through 2025, it's important for procurement managers, technical engineers, and production directors to grasp how complicated precision mechanical assemblies are so they can find the best solutions for their particular equipment needs.

Understanding Modern Precision Assembly Requirements

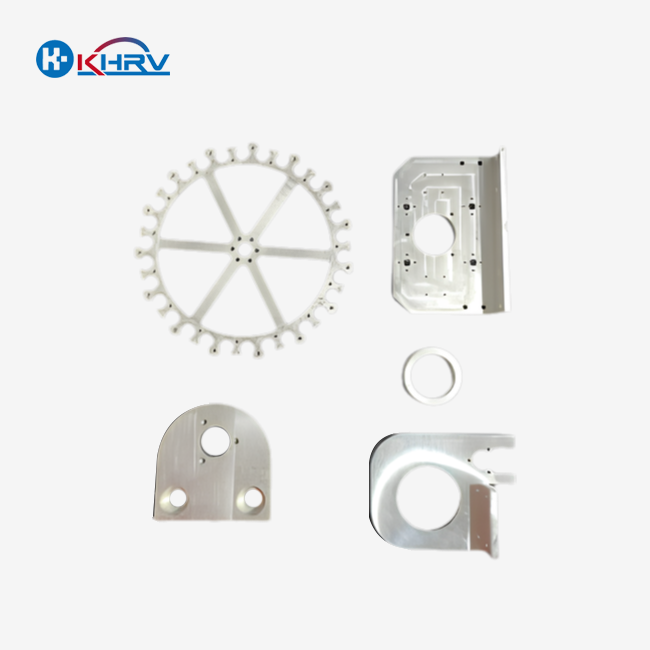

Manufacturing excellence rests on obtaining tolerances that were once believed to be unachievable. Today's precision mechanical assemblies may hold tolerances of ±0.005mm across several parts. This has led to major advances in automated systems and high-tech equipment. These assemblies use advanced materials like titanium alloys, carbide, and unique grades of stainless steel to make sure they work perfectly every time.

Real-time tolerance analysis and quality control technologies that keep an eye on assembly parameters all the time are now part of smart manufacturing processes. This improvement makes sure that every part fulfills strict standards before being added to bigger systems. Material science discoveries have opened up new possibilities for precision assemblies. Engineers can now request unusual metals and composites that have better performance characteristics.

For important uses, like packaging medical equipment and microelectronics, cleanroom environment norms have become standard. These controlled circumstances get rid of the risk of contamination and make sure that the quality of the assembly stays the same. Surface finishing methods have changed to make things work better, from making them more resistant to wear to adding specific coatings that make them work better in difficult situations.

Advanced Manufacturing Technologies Shaping Assembly Production

CNC milling and turning have become incredibly advanced, with five-axis capabilities that let you make intricate shapes that used to only be possible with numerous setups. Modern machining centers use adaptive control systems that change cutting parameters in real time to improve the quality of the surface finish while shortening cycle durations.

Precision grinding processes now provide mirror-like finishes on toughened materials, which is necessary for uses that need low friction and high durability. EDM has grown beyond its usual uses, allowing for the microfabrication of complex structures in unusual materials. Laser machining adds to traditional processes by giving you more accurate ways to remove material and texture surfaces.

Automated precision mechanical assemblies systems combine robotics with vision systems to ensure that thousands of parts are always in the right place. These systems use sensor integration technologies that give real-time feedback during assembly work. Thermal management factors now affect assembly design from the first idea to production, making sure that performance stays stable over a range of operating temperatures.

The process of surface hard anodizing has improved to make it more resistant to corrosion and wear. This is especially useful for aluminum alloy parts that need to work in tough conditions. These treatments make parts last longer and keep their size stable even when the working conditions change.

Industry-Specific Applications and Requirements

New energy production equipment needs parts that can handle a lot of stress while still being accurate over long periods of time. Components that work the same way throughout millions of cycles are needed for large-scale production lines. Battery manufacturing equipment has precision assemblies that keep alignment tolerances that are very important for the safety and quality of the products.

Robot manufacturing applications focus on precise assemblies that make it easy to regulate motion and place things exactly where they need to be. When designing an actuator, you need to think about how to reduce backlash and increase the efficiency of torque transmission. Vibration analysis methods assist in finding the best way to put together parts so that they work well under different load circumstances.

High-end CNC machine tool applications need assemblies that stay accurate even when they are cutting all the time. Spindle assemblies use cutting-edge bearing technology and precise balancing to make surfaces that are better than any other. Tool holding systems need to be very stiff so that tools may be changed quickly, which increases production.

In terms of precision assemblies, medical equipment applications have the strictest standards. When choosing materials, biocompatibility is important, and when choosing surface treatments and sealing procedures, sterilization compatibility is important. Optical alignment capabilities make it possible to accurately place imaging parts and surgical tools.

Material Selection and Engineering Considerations

Stainless steel grades are great for food processing and medical uses because they are resistant to corrosion and have strong mechanical qualities. Advanced metallurgical methods make grades that are stronger and lighter while still being easy to work with. Heat treatment procedures make the grain structure better so that it can resist fatigue better.

There are now high-strength aluminum alloys that can compete with steel and save a lot of weight. These alloys work well with precise machining and can be treated in many different ways on their surfaces. When designing an assembly, you need to think carefully about how thermal expansion affects tolerances across temperature ranges.

Brass parts are great for precision mechanical assemblies, electrical, and electronic uses because they conduct electricity well and resist corrosion. Machining properties make it possible to create complex shapes while keeping the dimensions stable. Brass types that don't include lead exceed environmental standards without losing performance.

As machining methods get better and prices go down, the uses for titanium alloys keep growing. These materials provide a great balance of strength and weight, and they are also quite resistant to corrosion. Specialized cutting tools and settings make machining quick and easy while keeping the surface intact.

Carbide parts are very strong and resistant to wear, which makes them great for cutting tools. Advanced grade formulas make the material tougher while keeping the cutting edge sharp. Precision grinding methods provide the surfaces with the finishes they need to cut well.

Quality Assurance and Compliance Standards

ISO9001:2015 accreditation sets the minimum quality management standards that ensure that production processes are always the same. These standards stress methods of continual improvement that raise the quality of a product while lowering its expenses. Document control systems make sure that everything can be traced back to the beginning of the manufacturing process.

EU RoHS compliance is now required for parts that will be sold in Europe. This means that dangerous compounds are not allowed, but performance standards must still be met. Testing protocols make sure that everyone in the supply chain is following the rules. There are now different materials and technologies that can address these needs without making things less functional.

Test reports that meet military standards give you confidence that parts will work even in the worst conditions. These tests include testing for accelerated life, exposure to different environments, and stress testing to make sure the product works. Statistical analysis of test data makes it possible to make predictions about how reliable important applications will be.

MEMS technology applications necessitate specific testing techniques that validate functionality at tiny scales. Despite their small size, these components have precision mechanical assemblies that work well. Nanotechnology applications require precision at the atomic level.

Supply Chain Optimization and Cost Management

Using strategic sourcing can save the cost of precision mechanical assemblies parts by 30% to 40% compared to using standard sources. These savings come from better production methods, better supply chain management, and economies of scale. When prices are clear, it's easier to organize your budget because you can make precise cost estimates.

Being able to respond quickly has become a competitive edge, with some suppliers promising to supply items in 48 hours for urgent needs. Small-batch flexible production is good for making prototypes and using them in small amounts. Scalable manufacturing capacity can change to meet different levels of demand without lowering quality.

Export compliance support makes buying things from other countries easier by taking care of paperwork, customs clearing, and coordinating logistics. Distributor networks make sure that local help is always available by covering a wide area. Technical collaboration goes beyond only providing parts to also include suggestions for improving processes.

OEM and ODM customization services let you develop solutions that are just right for your needs. You can try out sample service capabilities before you decide how many you want to make. Engineering support includes help with CAD modeling and suggestions for how to improve designs.

Future Trends and Technological Developments

Complex interior geometries that are unattainable through traditional machining are now possible thanks to the continued advancement of additive manufacturing technology in precision mechanical assemblies. Hybrid manufacturing methods use both additive and subtractive procedures to make components work better. High-performance alloys that can be used in demanding applications are now part of the material advances for additive processes.

Integrating artificial intelligence into manufacturing process control makes it easier to find the best cutting parameters and spot possible quality problems before they happen. Machine learning algorithms look at production data to find ways to speed up cycle times without lowering quality. Predictive maintenance features cut down on unplanned downtime.

Digital twin technology lets you test and improve assembly ideas in a virtual environment before making them in real life. These simulations show how things will work and provide ways to make them better. Integration with production systems lets you monitor and control things in real time.

Sustainable manufacturing methods are having a bigger and bigger effect on assembly production. These practices focus on using recyclable materials and techniques that use less energy. Lifecycle assessment looks at how materials affect the environment from extraction to disposal at the end of their useful life. Green manufacturing programs cut down on waste while keeping quality standards high.

Conclusion

Precision mechanical assemblies are still changing to satisfy the needs of applications that are becoming more and more demanding in a wide range of fields. Choosing partners who have both excellent manufacturing skills and a lot of technical knowledge, and a dedication to quality, is key to success. Strategic sourcing choices affect not only the cost of parts but also the long-term dependability of the product and its capacity to compete in the market. As manufacturing technologies get better, precision assemblies become progressively more important for making new things. Companies that buy better precision assemblies put themselves in a position to have long-term competitive advantages in their marketplaces.

Partner with KHRV for Superior Precision Mechanical Assembly Solutions

KHRV is the precision mechanical assemblies manufacturer you can trust. We use decades of CNC machining experience and the latest technology to make parts that are better than what the industry requires. Our cutting-edge facility has more than 50 modern CNC machines, such as Makino five-axis machining centers. This allows us to achieve even the strictest tolerance requirements while still meeting competitive delivery times.

We can work with a wide range of materials, including stainless steel, aluminum alloy, brass, titanium alloy, and carbide. We use CNC milling, turning, precision grinding, and EDM to do this. We are ISO9001:2015 certified and follow EU RoHS rules, which means we can guarantee the quality your applications need. Our flexible manufacturing method can meet your needs, whether you need prototype samples or large production runs.

Technical collaboration goes beyond making things to include suggestions for improving processes and creating bespoke cutting parameters. Our engineers work closely with your technical personnel to make sure that each part functions as well as possible while keeping costs as low as possible. Are you ready to see the KHRV benefits? Please email us at service@kaihancnc.com to talk about your needs for precise assembly and find out how our knowledge can help you with your product development projects.

References

1. Johnson, M.R. & Chen, L. (2024). "Advanced Manufacturing Techniques for Precision Mechanical Systems." Journal of Manufacturing Science and Engineering, Vol. 146, No. 8.

2. Thompson, K.A., Rodriguez, P.J. & Kumar, S. (2024). "Material Selection Criteria for High-Precision Assembly Applications." International Journal of Advanced Manufacturing Technology, Vol. 132, pp. 1247-1263.

3. Williams, D.S. & Anderson, B.K. (2023). "Quality Control Methodologies in Precision Mechanical Assembly Manufacturing." Precision Engineering Journal, Vol. 84, pp. 156-171.

4. Zhang, H., Mueller, F. & Nakamura, T. (2024). "Industry 4.0 Integration in Precision Assembly Production Systems." Manufacturing Letters, Vol. 35, pp. 89-97.

5. Roberts, J.E., Patel, M.N. & Lee, S.Y. (2023). "Cost Optimization Strategies for Global Precision Manufacturing Supply Chains." Supply Chain Management Review, Vol. 27, No. 6, pp. 34-42.

6. Brown, A.L., Garcia, R.M. & Tanaka, K. (2024). "Emerging Technologies in Microfabrication and MEMS Assembly Processes." Microsystems & Nanoengineering, Vol. 10, Article 45.