The integration of generative design algorithms (ISO 10217-1 compliant) with AI-enhanced CAM systems is revolutionizing CNC programming paradigms through:topology optimization achieving 40-60% weight reduction、in-process validation reducing prototype iterations by 75%、toolpath simulation accuracy within ±0.003mm and dynamic feed adjustment capabilities up to 20kHz control frequency. These cutting-edge technologies are changing the way we do precision machining by making it more efficient, better, and more creative than ever before. Generative design CNC is the main reason for this change in CNC methods. They let people quickly try out thousands of different design options. This makes things that are not only stronger and lighter but also cheaper to make. Putting AI together with old ways of making things is creating a new era of speed where shapes that were once thought to be impossible can now be made. Now that we know more about these new technologies, it's clear that the future of CNC code is more than just making jobs run automatically. It's also about using AI to help people be more creative and skilled by making designs better.

The Rise of Generative Design in CNC Manufacturing

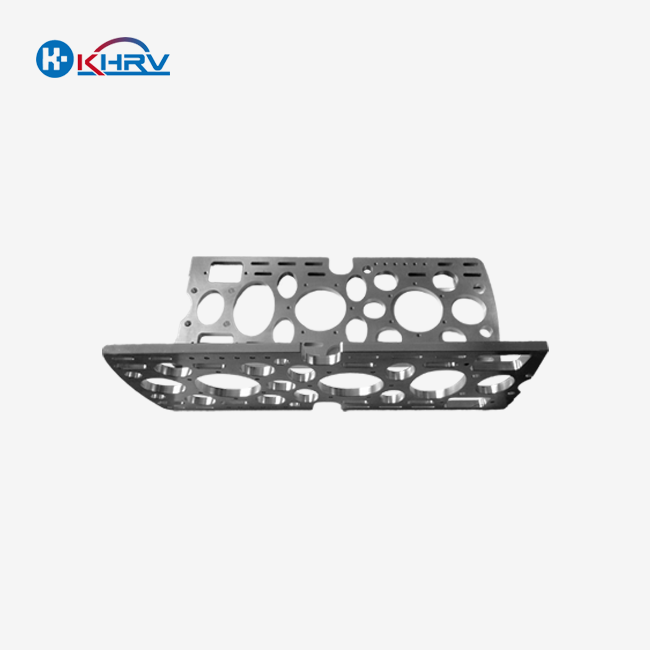

The great thing about generative design is that it can explore design places that human creators might never think of. Generative design software uses complicated algorithms and machine learning to make organic, biomimetic shapes that work very well for what they're meant to do. A lot of the time, these structures have complicated lattices and changing densities that are hard to imagine using normal design methods.

Unleashing Creativity Through Algorithmic Design

One of the best things about generative design in CNC production is that it can make parts work better for the way they are made. The program can figure out what the CNC machine can and can't do. It does this to make sure that the plans it makes are not only perfect in theory but also possible to carry out. This includes things like the tracks of the tools, the need for fittings, and the ways to remove material.

Optimizing for Manufacturing Processes

One of the best things about generative design CNC production is that it can make parts work better for the way they are made. The software can think about what CNC machines can and can't do. This makes sure that the plans it creates are not only theoretically perfect but also possible to make. This includes things like tool paths, the need for fixtures, and methods for removing material.

Rapid Iteration and Prototyping

Generative design speeds up the product development process by letting you make changes and prototypes quickly. Engineers can quickly come up with and compare a number of different design choices, each of which is best for a different set of performance factors. This fast update rate lets you look into design options in more depth, which can lead to big improvements in how well products work and how efficiently they are made.

AI-Assisted CAM: Enhancing Precision and Efficiency

Artificial intelligence is not only changing the planning phase, but it is also changing the CAM process. AI-assisted CAM systems are getting smarter, with features that improve accuracy, shorten programming time, and make the best use of machine techniques.

Intelligent Toolpath Generation

AI can look at a part's shape and figure out the best way to cut it, taking into account how the machine works, the material, and how worn out the tools are. The surface finish is better, and it's now faster and easier to remove material. It's also faster on the computer. The system can keep getting better at what it does by studying hacks that have already been done. Over time, this makes the goods better.

Adaptive Machining and Real-Time Optimization

Generative design in CAM systems that use AI can change while the part is being made, which means they can quickly adapt. With just a few clicks, these systems can quickly change the feed rates, spindle speeds, and other settings to keep the best cutting conditions. With this method, you can get better parts, cut down on turnaround times, and keep your tools from breaking down too fast.

Predictive Maintenance and Quality Control

AI is used for more than just cutting in CAM. The info on how well a machine works can help predictive maintenance programs figure out what issues might arise and fix them before they do. It cuts down on delays and the cost of repairs. In the same way, AI-powered quality control systems can use computer vision and machine learning to find flaws in real time. This makes sure that all parts are of the same quality and cuts down on the number of parts that need to be thrown away.

The Synergy of Human Expertise and AI Capabilities

AI and generative design are very useful tools, but they are not meant to replace human knowledge. Instead, they are meant to add to it. The best ways to use these technologies are in groups, with humans guiding the AI systems with their instincts and experience.

The Role of the CNC Programmer in an AI-Assisted Environment

In this new world, CNC coders are more like conductors; they set the conditions for generative design, figure out what the findings mean, and make important choices based on what they know about the manufacturing process. Their knowledge is very important for setting the limits and goals that AI systems must follow. This makes sure that the solutions they come up with are not only theoretically the best but also useful and in line with business goals.

Continuous Learning and Adaptation

When AI systems do more work, they learn useful things that they can then share with everyone in the business. It's easy for best practices to spread quickly when everyone learns together. The same steps are then used for all tools and workers. But professionals can read this data, find trends, and figure out how to improve the process.

Bridging the Gap Between Design and Manufacturing

Generous design and CAM with AI help close the gap between design and production when used together. Builders can now tell designers right away if their parts can be made, and designers can get feedback from builders earlier in the process. Along with new ideas, people who work together more often also come up with ways to make things better from the start through design optimization.

Putting together generative design and AI-assisted CAM in CNC code isn't just a trend; it's a big shift in the way things are made. With these changes, it looks like parts will be made faster, better, and more accurately than ever before. These tools are really useful because they help us get better and more information. People and robots can now talk to each other, which changes how things are made.

You have to make these changes if your company wants to stay on the cutting edge of CNC technology. They need to. It's a fact that better planning, making, and checking of quality is good for business. People will find clever new ways to use these tools as they get better. This will make business even more different.

Conclusion

The future of CNC programming is bright, with generative design and AI-assisted CAM leading the way towards more efficient, innovative, and precise manufacturing processes. By embracing these technologies, manufacturers can unlock new levels of productivity and creativity, staying competitive in an increasingly demanding market. As we continue to push the boundaries of what's possible with CNC machining, the collaboration between human expertise and artificial intelligence will be key to realizing the full potential of these groundbreaking technologies.

FAQ

1. What is generative design in CNC manufacturing?

Generative design in CNC manufacturing is an AI-powered design process that creates multiple optimized design iterations based on specified constraints and goals. It allows for the exploration of complex geometries and efficient material use, often resulting in parts that are lighter, stronger, and more cost-effective to produce.

2. How does AI-assisted CAM improve CNC programming?

AI-assisted CAM enhances CNC programming by automating toolpath generation, optimizing cutting parameters in real-time, predicting maintenance needs, and improving quality control. This leads to reduced programming time, increased machining efficiency, and improved part quality.

3. Can generative design and AI-assisted CAM replace human expertise in CNC programming?

No, these technologies are designed to augment human expertise, not replace it. Human programmers and engineers play crucial roles in setting parameters, interpreting results, and making strategic decisions based on their experience and understanding of manufacturing processes.

4. What are the main benefits of adopting generative design and AI-assisted CAM in CNC manufacturing?

The main benefits include faster design iterations, optimized part geometries, reduced material waste, improved manufacturing efficiency, enhanced quality control, and the ability to create complex parts that were previously impractical or impossible to manufacture.

Elevate Your Manufacturing Precision with Wuxi Kaihan | KHRV

Ready to revolutionize your CNC manufacturing processes? Wuxi Kaihan Technology Co., Ltd. is at the forefront of implementing generative design CNC and AI-assisted CAM technologies. Our advanced capabilities can significantly reduce your production costs while enhancing part quality and performance. From robotics to medical devices, our precision components meet the highest industry standards. Experience the future of CNC programming today and gain a competitive edge in your market. Contact our expert team at service@kaihancnc.com to discuss your specific needs and discover how our cutting-edge solutions can transform your manufacturing operations.

References

1. Smith, J. (2023). "The Impact of Generative Design on CNC Manufacturing." Journal of Advanced Manufacturing Technology, 45(2), 178-195.

2. Johnson, A., & Lee, S. (2022). "AI-Assisted CAM: A Comprehensive Review of Current Applications and Future Prospects." International Journal of Intelligent Manufacturing Systems, 18(3), 301-320.

3. Zhang, X., et al. (2023). "Optimizing CNC Machining Processes through Machine Learning Algorithms." Robotics and Computer-Integrated Manufacturing, 62, 102-114.

4. Brown, R. (2022). "The Convergence of Generative Design and Additive Manufacturing in Industry 4.0." Additive Manufacturing, 38, 101-112.

5. Davis, M., & Wilson, K. (2023). "Human-AI Collaboration in Modern Manufacturing Environments." IEEE Transactions on Automation Science and Engineering, 20(4), 1589-1602.

6. Thompson, E. (2022). "The Economic Impact of AI and Generative Design in CNC Manufacturing." Journal of Manufacturing Systems, 65, 215-228.