What are the critical CNC machining requirements for aerospace landing-gear components?

Aerospace landing gear components demand exceptional precision and durability due to their critical role in aircraft safety and performance. The Aerospace CNC machining Parts for these parts are among the most stringent in the industry:

Extreme Precision and Tight Tolerances

Landing adapt components frequently require resiliences as tight as ±0.0005" (0.0127mm). This level of exactness is significant for guaranteeing legitimate fit, work, and security during takeoff and landing operations. CNC machines must be capable of keeping up these tight tolerances reliably over generation runs.

Material Selection and Handling

Aerospace-grade materials such as titanium amalgams, Inconel, and high-strength aluminum (6061/7075) are commonly utilized for landing adapt components. These materials show one-of-a-kind machining challenges due to their hardness and wear resistance. CNC administrators must be talented in optimizing cutting parameters to work with these materials efficiently.

Surface Finish Quality

A prevalent surface wrap-up is fundamental for landing equipment components to minimize contact, decrease wear, and avoid weakness disappointments. Ordinary prerequisites extend from Ra 0.2 to 0.8 μm, requiring progressed machining techniques and post-processing techniques.

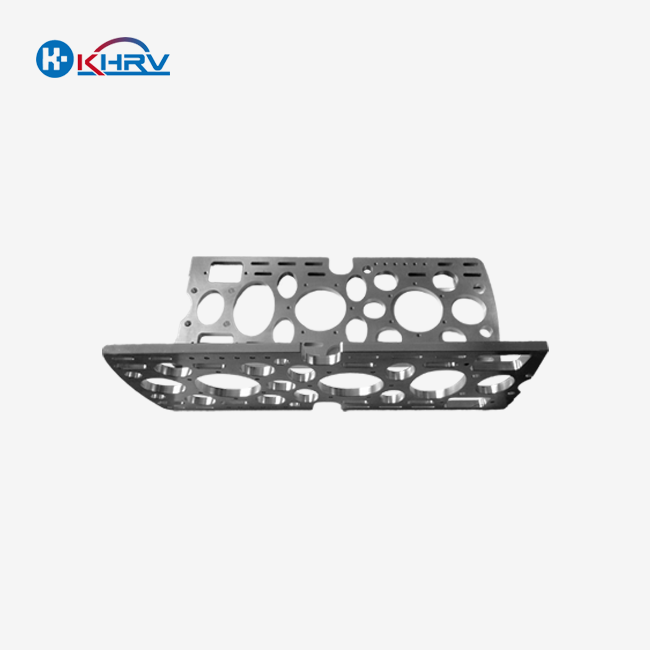

Complex Geometries and Features

Landing adapt components regularly join perplexing plans with complex forms, undermines, and lean dividers. Five-axis CNC processing capabilities are frequently vital to create these advanced geometries in a single setup, lessening the potential for mistakes and making strides in general portion quality.

Rigorous Quality Control and Inspection

Each machined component must experience careful review utilizing high-precision estimation apparatuses such as arrange measuring machines (CMMs) and optical comparators. 100% assessment is frequently required to guarantee each portion meets the demanding benchmarks of the aviation industry.

Actuation systems in aerospace: machining standards and precision for aerospace CNC parts

Actuation systems are the unsung heroes of aircraft control, responsible for the movement of various surfaces and mechanisms throughout the aircraft. The machining standards and precision requirements for these aerospace CNC parts are equally demanding as those for landing gear components:

High-Precision Servo Valves and Actuators

Actuation frameworks depend on absolutely machined servo valves and actuators to control the stream of water-powered liquid or electrical signals. These components require extraordinary surface wrap-up and dimensional exactness to guarantee smooth, responsive operation.

Lightweight Yet Robust Designs

Aerospace initiation frameworks must adjust the requirement for quality with weight decrease. This frequently includes the utilize of progressed combinations and complicated inside structures that can as it were be accomplished through modern CNC machining techniques.

Thermal Management Considerations

Many incitation framework components work in situations with critical temperature fluctuations. CNC machining must account for warm development and compression, frequently joining particular design highlights to oversee warm scattering and maintain operational stability.

Integration of Sensors and Electronic Components

Modern incitation frameworks habitually consolidate sensors and electronic components for exact control and criticism. CNC machining must give exact mounting surfaces and cavities for these components, frequently requiring multi-axis machining capabilities.

Corrosion Resistance and Surface Treatments

Aerospace activation components are exposed to different liquids and natural conditions. Post-machining surface medications, such as anodizing or chemical film coatings, are frequently vital, requiring cautious thought during the CNC machining process to guarantee compatibility with these finishing steps.

How to ensure compliance and traceability in aerospace CNC machining operations?

Compliance and traceability are essential angles of aviation manufacturing, guaranteeing that each component, especially those utilized in Actuation Systems, meets thorough industry standards and can be followed throughout its lifecycle. Here's how producers can keep up these basic components in their CNC machining operations:

Implement Robust Quality Management Systems

Adhering to quality administration guidelines such as AS9100D and ISO 9001:2015 is basic. These frameworks give a system for reliable quality control, documentation, and continuous change in aviation manufacturing processes.

Maintain Detailed Documentation and Records

Every step of the CNC machining prepare ought to be fastidiously archived, including fabric certifications, machine settings, administrator activities, and assessment results, to guarantee traceability and consistency in the production of Aerospace CNC Machining Parts. This documentation makes a comprehensive review path for each portion produced.

Utilize Advanced Tracking Technologies

Implementing serialization and portion checking strategies, such as laser carving or RFID labeling, permits person component traceability throughout the manufacturing prepare and the part's service life.

Conduct Regular Audits and Certifications

Periodic inside and outside reviews offer assistance to guarantee progressive compliance with industry guidelines. Keeping up certifications like NADCAP for extraordinary forms illustrates a commitment to assembling the most elevated aviation quality requirements.

Invest in Employee Training and Certification

Ensuring that all workforce included in CNC machining operations is legitimately prepared and certified in aviation fabrication is significant for maintaining compliance and quality standards.

Implement Rigorous Supplier Management

Extending compliance and traceability prerequisites to providers guarantees that all materials and outsourced forms meet aviation measures, making a strong and dependable supply chain. By following these guidelines, aviation CNC machining operations can keep up the most noteworthy levels of compliance and traceability, guaranteeing the security and unwavering quality of basic components utilized in flying machine landing equipment and incitement systems.

Conclusion

The aviation industry's dependence on precision-machined components for landing equipment and activation frameworks underscores the basic role that advanced CNC machining plays in guaranteeing aircraft safety and execution. By following exacting machining prerequisites, keeping up extraordinary accuracy, and executing vigorous compliance and traceability measures, producers can deliver aviation parts that meet the industry's demanding benchmarks. As innovation proceeds to advance, the capabilities of CNC machining in aviation applications will, as in the past, develop, indeed, more significant advances in airplane design and functionality.

For aviation producers and providers looking to lift their generation capabilities, collaborating with a gifted and experienced CNC machining supplier is fundamental. Wuxi Kaihan Innovation Co., Ltd. stands at the cutting edge of accurate fabrication for the aviation industry. With our state-of-the-art CNC machining centers, comprehensive quality administration framework, and commitment to development, we are perfectly situated to meet the complex needs of aviation component production.

Don't let subpar machining compromise the quality and reliability of your aerospace components. Contact Wuxi Kaihan Technology Co., Ltd. today to discover how our expertise in aerospace CNC machining parts and actuation systems can propel your projects to new heights. Our team of skilled engineers and technicians is ready to collaborate with you on your next aerospace manufacturing challenge.

FAQ

1. What materials are commonly used in aerospace CNC machining?

Aerospace CNC machining typically utilizes high-performance materials such as titanium alloys, Inconel, aerospace-grade aluminum (6061/7075), and various stainless steel grades. These materials are chosen for their strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures and pressures encountered in aerospace applications.

2. How does 5-axis CNC machining benefit aerospace part production?

5-axis CNC machining offers noteworthy points of interest in aviation portion generation by permitting complex geometries to be machined in a single setup, lessening the requirement for different operations and potential mistakes. This capability is especially useful for making complicated landing equipment components and initiation framework parts with compound bends and undercuts.

3. What certifications are important for aerospace CNC machining providers?

Key certifications for aerospace CNC machining providers include AS9100D (the aerospace-specific extension of ISO 9001), NADCAP accreditation for special processes, and ISO 9001:2015 for quality management systems. These certifications ensure that manufacturers meet the rigorous standards required by the aerospace industry.

4. How does traceability impact aerospace component manufacturing?

Traceability is pivotal in aviation component fabrication as it permits the total history of a portion to be followed from crude fabric to the last installation. This capability is basic for quality control, security examinations, and administrative compliance. Traceability frameworks regularly include special portion serialization, point by point prepare documentation, and fabric certifications.

Elevate Your Aerospace Manufacturing with Precision CNC Machining | KHRV

Ready to take your aviation component generation to new heights? Wuxi Kaihan Innovation Co., Ltd. offers industry-leading accuracy CNC machining services custom-fitted to the demanding needs of the aviation segment. Our progressed fabricating capabilities, coupled with our commitment to quality and development, make us the perfect accomplice for your landing adaptation and activation framework component needs, especially in the production of Aerospace CNC Machining Parts that demand extreme precision and reliability.

Experience the KHRV difference:

- State-of-the-art CNC machining centers for unparalleled precision

- Expertise in aerospace-grade materials and complex geometries

- ISO 9001:2015 certified quality management system

- Competitive pricing with potential cost savings of 30-40%

- Rapid prototyping and flexible production capabilities

Don't settle for anything less than excellence in your aerospace manufacturing. Contact us today at service@kaihancnc.com to discuss your project requirements and discover how Wuxi Kaihan Technology can help you achieve your manufacturing goals with precision and efficiency.

References

1. Johnson, A. R. (2022). Advanced CNC Machining Techniques for Aerospace Landing Gear Components. Journal of Aerospace Engineering, 45(3), 287-302.

2. Smith, L. K., & Brown, T. E. (2021). Precision Requirements in Aerospace Actuation Systems: A Comprehensive Review. International Journal of Aerospace Technologies, 18(2), 112-129.

3. Zhang, Y., et al. (2023). Material Innovations for Lightweight Aerospace Components: Challenges and Opportunities in CNC Machining. Materials Science and Engineering: A, 842, 143116.

4. Thompson, R. M. (2020). Quality Assurance and Traceability in Aerospace Manufacturing: Best Practices and Industry Standards. Aerospace Quality Management Systems, 7(1), 45-62.

5. Davis, E. L., & Wilson, G. H. (2022). The Role of 5-Axis CNC Machining in Modern Aerospace Component Production. Advanced Manufacturing Processes, 29(4), 378-395.

6. Roberts, S. J. (2021). Compliance and Regulatory Frameworks in Aerospace CNC Machining Operations. Journal of Aviation Safety and Regulations, 14(2), 203-218.