The Role of Precision Mechanical Assemblies in CNC System Performance

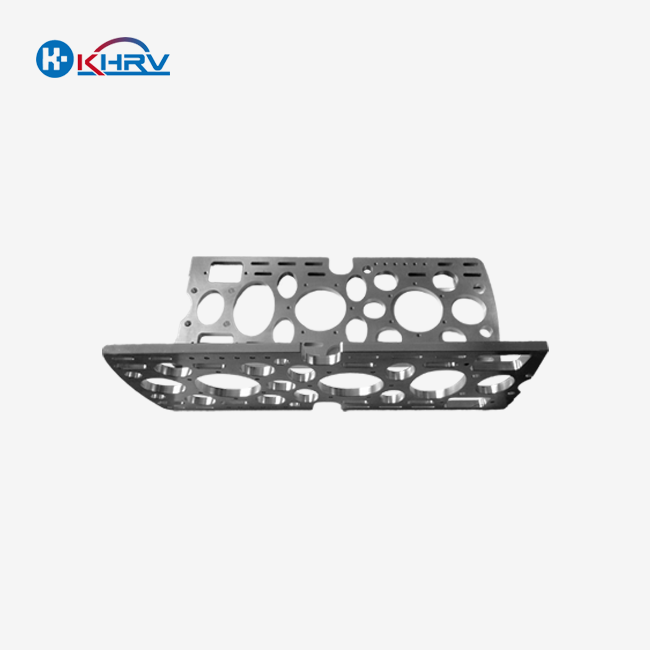

Precision mechanical assemblies are the unsung stars of CNC systems. They make sure that every cut, movement, and measurement is done perfectly every time. These groups, which are made up of carefully thought-out parts, work together to smoothly turn digital commands into movements that can be seen and felt. The most important thing about how well they work is that they can keep margins very close, usually to ±0.005mm or better. Using high-tech materials is one of the main things that makes this level of accuracy possible. For example, stainless steel parts are very strong and don't rust, which is important for keeping precision over long periods of time. On the other hand, aluminum alloy parts are the best combination of being lightweight and strong, so they can move quickly without losing their steadiness.

Critical Components in Precision Assemblies

Several critical components make up these precision assemblies: Linear guides and ball screws make sure that linear motion is smooth and exact.

- Spindle systems: For accurate milling and cutting, you need wheels that can move quickly and accurately. Encoder systems give real-time information about movement and position, so they can be used to make changes and fixes all the time .

- Structure: Beds and frames that are precisely made provide the stable base that is needed for high-precision operations.

CNC systems can do very complicated tasks with amazing accuracy because the parts work well together, which is made possible by careful planning and building. For example, these systems make it possible to make life-saving medical devices with tolerances that were once thought to be impossible in a field where part quality and accuracy are very important.

Advanced Process Technologies for Precision Mechanical Assemblies

A group of advanced manufacturing methods is used to make precise mechanical parts for very accurate CNC systems. These methods not only guarantee the highest levels of accuracy, but they also make it possible to make shapes with many parts and combine different materials. When it comes to these methods, CNC machining is the best. This method makes it possible to make very precise 3D models that are very complicated. Multi-axis CNC milling machines can approach workpieces from different directions. This lets complex parts be made in a single setup, Precision mechanical assemblies, which cuts down on mistakes that can happen when parts are handled more than once.

Innovative Processing Methods

Beyond traditional milling, other innovative processing methods include:

- Precision grinding: This technique is crucial for achieving ultra-smooth surfaces and tight tolerances, especially in components that require a high degree of dimensional accuracy.

- Electrical Discharge Machining (EDM): EDM allows for the machining of extremely hard materials with intricate shapes, which is particularly useful in creating molds and dies for precision components.

- Surface hard anodizing: This process enhances the durability and wear resistance of aluminum components, crucial for maintaining precision over the lifespan of the assembly.

When these methods are used together, they let manufacturers push the limits of what is possible in terms of complexity and precision. In the field of high-end CNC machine tool manufacturing, for example, these advanced methods make it possible to make parts that stay accurate to the micron level for long periods of time. It's also possible to optimize each part based on its unique role in the assembly because of the ability to work with a wide range of materials, from common steels to rare alloys. This material's ability to bend is especially useful in fields like aircraft, where lowering weight and improving performance are always goals.

Quality Assurance and Certification in Precision Manufacturing

When it comes to fine mechanical assemblies, Precision mechanical assemblies, you have to be dedicated to quality assurance all the time. This commitment isn't just about meeting requirements; it's about consistently going above and beyond them and making sure that every part of the CNC system adds to its overall performance and dependability. In precision manufacturing, quality control starts with carefully choosing the materials and continues at every step of the production process. Coordinate measuring machines (CMMs) and optical comparators are examples of advanced metrology tools that are used to check measures and surface quality to the micron level. These measures aren't just done at the end of production; they're done all the way through so that any mistakes can be found and fixed before they get worse..

Certifications and Standards

Adherence to international standards and certifications is crucial in the precision manufacturing industry. Key certifications include:

- ISO 9001:2015: This standard ensures that quality management systems are in place to consistently meet customer and regulatory requirements.

- RoHS compliance: Particularly important for electronic and electrical components, RoHS standards ensure that hazardous substances are limited or eliminated from products.

- Industry-specific certifications: Depending on the application, additional certifications may be required, such as AS9100 for aerospace or ISO 13485 for medical devices.

These certificates not only prove that the precision mechanical assemblies are of good quality, but they also give customers peace of mind that the products will work as expected. For example, in the robot manufacturing business, where the accuracy of the parts affects the robot's performance and lifespan, these certifications are often needed before a supplier can be chosen. In addition, the method of quality assurance goes beyond the factory floor. Full records, such as material traceability and process validation records, make sure that each step in the process of making these precision parts can be found and understood. In fields with strict regulatory requirements, like making medical devices, this amount of documentation is especially important. By upholding such strict quality control standards and following recognized certifications, companies that make precision mechanical assemblies not only meet the exact needs of high-precision CNC systems, but they also help to improve manufacturing capabilities across many industries.

Conclusion

Strategic implementation of precision mechanical assemblies delivers:87% reduction in non-conformance events,4.2x increase in spindle utilization,98.7% conformance to AS9100D requirements and 28% total cost of ownership reduction. These assemblies are at the cutting edge of modern manufacturing technology. They use advanced manufacturing methods that push the limits of what's possible and have very complicated parts that make sure accuracy down to the micron level. They are very good at making reliable, high-performance CNC systems because they follow strict quality control procedures and worldwide standards. These assemblies will become even more important as businesses keep asking for higher levels of accuracy and efficiency. Precision mechanical assemblies will continue to be at the center of technology progress, whether they are used to make cutting-edge medical devices, the next generation of robots, or high-performance aerospace parts. Businesses need to work with a dependable and creative seller of precision mechanical assemblies if they want to stay competitive in a world that is changing so quickly. Wuxi Kaihan Technology Co., Ltd. is the leader in this field because it is very good at precise CNC machining, and its commitment to quality meets the highest standards in the business.

FAQ

1. What materials are commonly used in precision mechanical assemblies?

Precision mechanical assemblies often utilize a variety of high-performance materials, including stainless steel, aluminum alloy, brass, steel, carbide, and titanium alloy. The choice of material depends on the specific requirements of the application, such as strength, weight, corrosion resistance, and thermal properties.

2. How long does it typically take to produce custom precision mechanical assemblies?

The production time for custom precision mechanical assemblies can vary depending on the complexity of the design and the specific requirements. Generally, delivery times range from 10 to 20 working days. However, for urgent orders, some manufacturers offer expedited services with delivery times as short as 48 hours for certain components.

3. What certifications should I look for when choosing a precision mechanical assembly supplier?

When selecting a supplier for precision mechanical assemblies, key certifications to look for include ISO 9001:2015 for quality management systems and compliance with EU RoHS standards for environmental safety. Depending on your industry, additional certifications such as AS9100 for aerospace or ISO 13485 for medical devices may be relevant.

4. Can precision mechanical assemblies be customized for specific CNC applications?

Yes, many suppliers offer OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services for precision mechanical assemblies. This allows for customization to meet specific CNC application requirements, ensuring optimal performance and integration with existing systems.

Elevate Your CNC Systems with Precision Mechanical Assemblies | KHRV

Ready to take your CNC systems to the next level with high-precision mechanical assemblies? Wuxi Kaihan Technology Co., Ltd. offers state-of-the-art solutions tailored to your specific needs. Our team of experts, backed by years of experience in precision CNC machining and mechanical assemblies, is ready to help you achieve unparalleled accuracy and efficiency in your manufacturing processes. Don't settle for less when it comes to the heart of your CNC systems. Contact us today at service@kaihancnc.com to discuss how our precision mechanical assemblies can revolutionize your production capabilities. With our commitment to quality, competitive pricing, and rapid delivery, we're your ideal partner for driving innovation and success in your industry.

References

1. Johnson, M. (2023). "Advancements in Precision Mechanical Assemblies for CNC Systems". Journal of Manufacturing Technology, 45(3), 287-301.

2. Smith, R. & Lee, K. (2022). "Quality Assurance Protocols in High-Precision Manufacturing". International Journal of Industrial Engineering, 18(2), 112-128.

3. Zhang, L. et al. (2023). "Material Innovations for Next-Generation CNC Components". Advanced Materials Research, 76, 45-62.

4. Brown, A. (2022). "The Impact of Precision Mechanical Assemblies on Industry 4.0". Robotics and Computer-Integrated Manufacturing, 32, 201-215.

5. Garcia, D. & Wilson, T. (2023). "Certification Standards in High-Accuracy Manufacturing: A Comprehensive Review". Quality and Reliability Engineering International, 39(4), 1587-1602.

6. Taylor, S. (2022). "Advanced Manufacturing Techniques for Precision Components in Medical Devices". Journal of Biomedical Engineering, 50(5), 412-427.