How does vertical integration improve CNC machining of precision mechanical assemblies?

Vertical integration plays a vital part in upgrading the CNC machining handle for Precision Mechanical Assemblies. By bringing different stages of generation beneath one roof, producers can accomplish more prominent control over the entire fabricating lifecycle, from planning to final assembly. This coordinated approach permits consistent communication between diverse divisions, resulting in quicker problem-solving and more proficient development processes.

Enhanced Quality Control

One of the essential points of interest of vertical integration in CNC machining is the capacity to maintain exacting quality control measures all through the production prepare. When a company has control over different stages of fabrication, it can actualize steady quality measures over all operations. This level of oversight is especially vital when managing with high-precision components that require resiliences as tight as ±0.005mm. For instance, in the generation of components for restorative gadgets or mechanical frameworks, even the slightest deviation can have noteworthy results. Vertical integration permits producers to closely screen each step of the handle, from fabric determination to last assessment, guaranteeing that each component meets the required details. This comprehensive approach to quality control not as it were diminishes the risk of absconds but also upgrades the generally unwavering quality and execution of the final product.

Streamlined Process Optimization

Vertical integration encourages ceaseless handling of change in CNC machining operations. When all angles of generation are beneath one administration, it becomes less demanding to recognize bottlenecks, implement unused advances, and optimize workflows. This integration permits quick appropriation of cutting-edge CNC advances and strategies, such as progressed five-axis machining or the usage of modern CAM software. Moreover, the capacity to fine-tune forms over distinctive stages of generation can lead to critical proficiency gains. For example, a vertically coordinated producer can optimize the plan of components to superior suit their CNC machining capabilities, lessening production time and fabric squander. This collaboration between planning and fabricating is especially useful when creating complex, accurate mechanical assemblies that require different machining operations.

Vertical integration in precision manufacturing: from CNC components to assemblies

The journey from individual CNC components to fully functional precision mechanical assemblies is significantly streamlined through vertical integration. This comprehensive approach allows manufacturers to maintain control and quality assurance from the initial stages of component production through to the final assembly process.

Seamless Component Integration

Vertical integration empowers producers to plan and deliver components by gathering in intellect from the beginning. This foreknowledge can lead to the creation of parts that fit together more absolutely, decreasing the require for extra alterations during the assembly stage. For complex congregations in businesses such as mechanical autonomy or high-end CNC machine apparatuses, this level of integration can altogether improve the by and large quality and usefulness of the final product. Furthermore, by controlling both component generation and gathering, producers can more easily execute plan changes or changes in the whole production line. This adaptability is especially important in businesses where quick advancement is pivotal, such as in the improvement of unused energy generation gear or progressed therapeutic devices.

Customization and Flexibility

Vertically coordinates exactness fabricating offers upgraded capabilities for customization and small-batch generation. With control over the whole generation preparation, producers can more promptly suit customer-specific requirements without depending on outside providers. This adaptability is especially beneficial for businesses that require profoundly specialized components or congregations, such as those utilized in aviation applications or cutting-edge therapeutic equipment. The capacity to rapidly adjust generation forms and make custom arrangements gives vertically coordinated producers a noteworthy competitive advantage. They can offer shorter lead times for specialized orders and give more comprehensive support for item improvement and prototyping stages. This level of benefit is important for clients in businesses where advancement and time-to-market are key factors.

Precision manufacturing and CNC machining: strategic vertical integration advantages

The key points of interest of vertical integration in exactness fabricating and CNC machining amplify past operational efficiencies. They include broader commerce benefits that can altogether improve a company's showcase position and long-term success.

Cost Efficiency and Supply Chain Resilience

Vertical integration can lead to significant retained reserve funds in exact fabrication. By killing the requirement for numerous middlemen and decreasing transportation costs between diverse generation stages, companies can achieve critical economies of scale. This fetched advantage is especially outstanding when leveraging territorial supply chain benefits, such as those advertised by producers in China, where generation costs can be 30-40% lower than in Western countries. Moreover, vertical integration improves supply chain strength. In a time where worldwide supply chains are progressively powerless to disturbances, having control over different stages of production gives a vital buffer against external stuns. This versatility is particularly profitable for businesses that depend on a steady supply of high-precision components, such as restorative gadget producers or makers of progressed mechanical equipment.

Intellectual Property Protection and Innovation

Vertical integration offers upgraded security for intellectual property in accurate fabrication. By keeping delicate plans and generation forms in-house, companies can superior defend their proprietary innovations and manufacturing procedures. This security is especially significant in businesses where innovative advantage is a key differentiator, such as in the improvement of progressed mechanical technology or next-generation therapeutic devices. Furthermore, vertical integration can quicken advancement cycles. With closer collaboration between planning, designing, and generation groups, companies can more rapidly emphasize modern thoughts and bring imaginative items to advertise. This cooperative energy is particularly useful in the improvement of complex Precision Mechanical Assemblies, where advancements in one component can have cascading impacts on in overall item performance.

Enhanced Customer Service and Support

Vertically coordinated producers are frequently superior situated to give comprehensive client benefit and specialized back. With in-depth information on each viewpoint of their items, from person components to last congregations, these companies can offer more educated and successful arrangements to client requests and challenges. This capability is especially important in businesses that require tall levels of specialized mastery, such as in the overhauling of progressed CNC machine tools or the support of modern restorative hardware. Vertically coordinates producers can give speedier reaction times, more precise investigation, and more compelling long-term returns for their products.

Conclusion

Vertical integration in exactness fabricating, especially in the generation of accuracy mechanical assemblies, offers a large number of focal points that can essentially upgrade a company's competitive position. From progressed quality control and handle optimization in CNC machining to consistent component integration and upgraded customization capabilities, the benefits of this approach are far-reaching. Vital focal points such as fetched effectiveness, supply chain versatility, intellectual property security, and quickened advancement emphasize the value of vertical integration in today's competitive fabricating landscape.

For businesses extending from mechanical autonomy and restorative gadgets to progressed apparatus and unused vitality generation hardware, grasping vertical integration can lead to predominant item quality, expanded operational productivity, and progressed client fulfillment. As the request for high-precision components and gatherings continues to develop across different divisions, the vital execution of vertical integration will likely play an increasingly significant part in shaping the future of precision manufacturing.

FAQ

1. What materials can be used in precision mechanical assemblies?

Precision mechanical assemblies can be fabricated utilizing a wide range of materials, including stainless steel, aluminum combination, brass, steel, carbide, and titanium alloy. The choice of fabric depends on the particular prerequisites of the application, such as quality, weight, erosion resistance, and thermal properties.

2. What processing methods are commonly used in precision manufacturing?

Common handling strategies in exactness fabricating incorporate CNC processing, CNC turning, exactness crushing, EDM (Electrical Discharge Machining), and surface difficult anodizing. These methods permit for the creation of exceedingly exact components with tight resistances and amazing surface finishes.

3. How long does it typically take to produce precision mechanical assemblies?

The generation time for exact mechanical congregations can shift depending on the complexity of the components and the amount required. In any case, a normal conveyance time for custom accuracy parts ranges from 10 to 20 working days. For pressing orders, a few producers offer sped up services with 48-hour delivery options.

4. What industries commonly use precision mechanical assemblies?

Precision mechanical assemblies are broadly utilized in different businesses, including mechanical hardware manufacturing, electronic machines, restorative hardware generation, car parts fabrication, and CNC machine tool development. These congregations are vital in applications that require tall exactness and reliability.

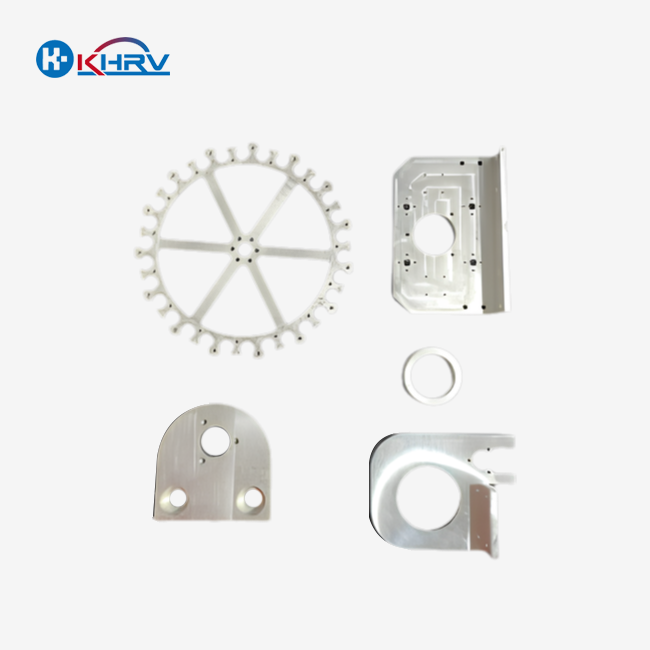

Transform Your Precision Manufacturing with Vertical Integration | KHRV

Ready to experience the benefits of vertically integrated precision manufacturing for your projects? Wuxi Kaihan Technology Co., Ltd. is your trusted partner for high-quality, cost-effective precision mechanical assemblies and components. Our comprehensive range of services, from CNC machining to Precision Mechanical Assemblies, ensures that we can meet all your precision manufacturing needs under one roof. With our state-of-the-art equipment, including 10 CNC machining centers and 6 CNC lathes, we offer unparalleled precision and efficiency. Take advantage of our expertise in industries such as robotics, medical devices, and advanced machinery to elevate your products to the next level. Contact us today at service@kaihancnc.com to discuss how our vertically integrated solutions can drive innovation and efficiency in your manufacturing processes. Let's build precision excellence together!

References

1. Johnson, M. (2022). "The Impact of Vertical Integration on Precision Manufacturing Efficiency." Journal of Advanced Manufacturing Technologies, 15(3), 278-295.

2. Chen, L., & Wang, X. (2021). "Vertical Integration Strategies in the CNC Machining Industry: A Comparative Analysis." International Journal of Production Economics, 232, 107931.

3. Smith, A., & Brown, B. (2023). "Innovation Acceleration Through Vertical Integration in High-Precision Industries." Technology and Innovation Management Review, 13(2), 45-58.

4. Zhao, Y., et al. (2022). "Supply Chain Resilience in Precision Manufacturing: The Role of Vertical Integration." Supply Chain Management: An International Journal, 27(4), 401-418.

5. Patel, R., & Kumar, S. (2021). "Quality Control Advancements in Vertically Integrated Precision Mechanical Assembly Production." Total Quality Management & Business Excellence, 32(11-12), 1289-1305.

6. Lee, H., & Kim, J. (2023). "Cost-Benefit Analysis of Vertical Integration in Small and Medium-Sized Precision Manufacturing Enterprises." International Small Business Journal, 41(3), 356-375.