What role do CNC cutting tools and CNC machining play in the mass customization of consumer products?

CNC cutting apparatuses and machining forms are urgent in empowering mass customization of consumer goods. These progressive innovations offer unparalleled exactness and adaptability, permitting producers to deliver complex and changed plans with surprising productivity. By utilizing computer-controlled machines, companies can quickly adjust generation lines to make assorted item varieties without critical retooling or downtime.

Precision and Consistency in Customization

The part of CNC machining in mass customization is multifaceted. Firstly, it guarantees remarkable exactness in fabricating, keeping up tight tolerances of ±0.005mm, which is pivotal for making high-quality, customized items that meet exact details. This level of exactness is especially crucial in businesses such as therapeutic gadget manufacturing, where component quality and accuracy are paramount.

Flexibility in Design and Production

Secondly, CNC machining offers surprising adaptability. Producers can rapidly switch between distinctive item plans or make minor alterations to existing ones without the requirement for broad retooling. This versatility is particularly useful for robot fabricating companies and high-end CNC machine instrument producers, where progressing hardware updates and component substitutions are common.

Efficiency in Small Batch Production

Furthermore, CNC machining exceeds expectations in small-batch generation, a foundation of mass customization. It permits cost-effective generation of restricted amounts, making it possible to offer personalized items without the requirement for huge production runs. This capability is especially invaluable for therapeutic gadget producers, who frequently require small clusters of exceedingly specialized components.

Mass customization via CNC machining: CNC cutting tools enabling consumer product variability

The approach of progressive CNC cutting devices has essentially extended the possible outcomes for consumer product customization. These instruments, coupled with modern CNC machining centers, permit the creation of complex geometries and complex, subtle elements that were already challenging or inconceivable to accomplish at scale.

Expanding Design Possibilities

CNC cutting apparatuses empower producers to work with a wide range of materials, from metals to plastics, opening up modern roads for item customization. This flexibility is vital for businesses like unused vitality generation gear manufacturing, where components are regularly required to be custom-made to particular natural conditions or vitality era methods.

Rapid Prototyping and Iteration

Another key angle of CNC machining in mass customization is its part in fast prototyping. Producers can rapidly create model parts, test them, and emphasize plans, quickening the product development cycle. This capability is especially profitable for robot fabricating companies and high-end CNC machine apparatus producers, where development and execution upgrades are consistent focuses.

Customization at Various Stages

CNC machining permits customization at diverse stages of the fabrication prepare. From making custom molds for infusion molding to straightforwardly machining final items, the innovation offers adaptability in how and when customization happens. This flexibility is advantageous over all businesses, permitting companies to optimize their generation forms for the most extreme productivity and customization potential.

CNC components and machining strategies for mass-custom consumer manufacturing

To completely use CNC machining for mass customization, producers must utilize particular components and methodologies custom-made to this one-of-a-kind generation approach. These components work in concert to make a fabricating environment that's both adaptable and efficient.

Advanced CNC Machine Components

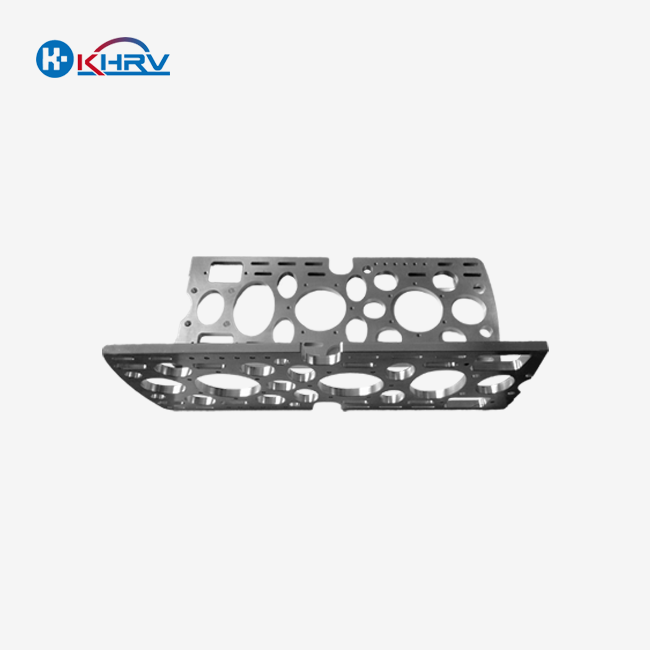

The key to mass-custom fabricating is high-precision CNC machine components. These incorporate multi-axis machining centers, which permit complex geometries to be made in a single setup, diminishing production time and increasing accuracy. Wuxi Kaihan Innovation Co., Ltd., for instance, utilizes progressed CNC machining centers and EDM wire machines, enabling them to create complex parts with high precision.

Adaptive Manufacturing Strategies

Implementing versatile fabrication techniques is vital for mass customization. This includes utilizing adaptable installations and tooling frameworks that can be rapidly reconfigured for diverse item varieties. Such procedures are especially useful for businesses like restorative gadget manufacturing, where product decisions can shift significantly between orders.

Integration of CAD/CAM Software

The integration of a progressed CAD/CAM computer program with CNC machines is fundamental for streamlining the move from custom plans to wrapped up items. This computer program permits fast programming of CNC machines, empowering fast adjustment to unused item details. For robot fabricating companies and high-end CNC machine device producers, this integration encourages the persistent development and execution improvements that are essential in these fast-evolving industries.

Quality Control and Consistency

Maintaining reliable quality over customized items is a one-of-a-kind challenge in mass-custom fabricating. Actualizing strong quality control measures, such as in-process estimation and versatile machining strategies, guarantees that each customized thing meets the required details. This is especially vital for therapeutic gadget producers, where component quality directly impacts item usefulness and safety.

Supply Chain Optimization

Maintaining reliable quality over customized items is a one of a kind challenge in mass-custom fabricating. Actualizing strong quality control measures, such as in-process estimation and versatile machining strategies, guarantees that each customized thing meets the required details. This is especially vital for therapeutic gadget producers, where component quality straightforwardly impacts item usefulness and safety.

Conclusion

The integration of CNC machining into mass customization forms is reshaping the scene of customer item fabrication. By empowering exceptional levels of item changeability, exactness, and effectiveness, CNC innovation is clearing the way for a future where personalized items are not fair an extravagance, but a standard desire. As businesses proceed to embrace and refine these innovations, we can expect indeed more prominent headways in customization capabilities, leading to items that more closely align with person buyer needs and preferences.

For companies looking to remain competitive in this advancing advertise, joining forces with experienced CNC machining suppliers is significant. Wuxi Kaihan Innovation Co., Ltd. stands at the cutting edge of this insurgency, advertising cutting-edge CNC machining services that empower mass customization across different businesses. With our state-of-the-art gear, including 10 CNC machining centers and 6 CNC machines, we're prepared to handle assorted customization needs with accuracy and efficiency.

Whether you're in modern vitality generation hardware, robot fabricating, high-end CNC machine instrument fabricating, or restorative gadget generation, our expertise can offer assistance you use the control of CNC machining for mass customization. Take the following step towards revolutionizing your item offerings and contact us nowadays to investigate how our CNC machining arrangements can change your fabricating processes.

FAQ

1. What are the main benefits of using CNC machining for mass customization?

CNC machining offers tall accuracy, adaptability in plan, productive small-batch generation, and the capacity to work with different materials, making it perfect for making customized items at scale.

2. How does CNC machining impact product development cycles?

CNC machining empowers fast prototyping and cycle, essentially quickening the item advancement cycle and permitting for speedy plan adjustments based on testing and feedback.

3. What industries benefit most from CNC machining in mass customization?

Industries such as restorative gadget fabricating, mechanical autonomy, aviation, and car advantage enormously from CNC machining's capacity to create exact, customized components efficiently.

4. How does CNC machining maintain quality consistency in mass-custom manufacturing?

CNC machining maintains quality consistency through precise computer control, in-process measurements, and adaptive machining techniques, ensuring each customized item meets required specifications.

Transform Your Manufacturing with Precision CNC Machining | KHRV

Ready to revolutionize your product offerings with mass customization? Wuxi Kaihan Technology Co., Ltd. is your partner in precision CNC machining for customized manufacturing. Our state-of-the-art facilities and experienced team are equipped to handle your most complex customization needs. From new energy production equipment to medical devices, we offer unparalleled precision, quick turnaround times, and cost-effective solutions. Don't let your competition get ahead – embrace the future of manufacturing today. Contact us at service@kaihancnc.com to discuss how we can elevate your production capabilities and bring your custom product visions to life.

References

1. Smith, J. (2023). "The Rise of Mass Customization in Manufacturing". Journal of Advanced Manufacturing Technologies, 15(3), 245-260.

2. Chen, L., & Wang, H. (2022). "CNC Machining Strategies for Personalized Product Manufacturing". International Journal of Production Research, 60(2), 178-195.

3. Thompson, M. K. (2021). "Integrating CAD/CAM Systems for Efficient Mass Customization". Advances in Manufacturing Technology, 8(4), 312-328.

4. Rodriguez, A., & Lee, S. (2023). "Quality Control Challenges in Mass Customization: A CNC Perspective". Quality Engineering, 35(1), 87-102.

5. Park, Y., & Kim, J. (2022). "Supply Chain Optimization for Mass Customization in the CNC Industry". Supply Chain Management: An International Journal, 27(4), 501-518.

6. Liu, X., & Zhang, W. (2023). "The Future of Consumer Products: Mass Customization through Advanced CNC Technologies". Journal of Manufacturing Systems, 66, 215-230.