China's precise manufacturing industry is still growing very quickly, especially when it comes to making unique parts like CNC motor mount plates. These important parts are what make motor attachments safe in robotics, medical devices, new energy tools, and high-end CNC machines. The best manufacturers in China offer reasonable prices and advanced machining. Compared to European and American suppliers, they can save 30% to 40% on costs while still meeting strict quality standards. Their skills include CNC milling, precision turning, and EDM, and they can work with materials ranging from aluminum alloy to titanium for a wide range of industry uses.

Wuxi Kaihan Technology Co., Ltd. (KHRV)

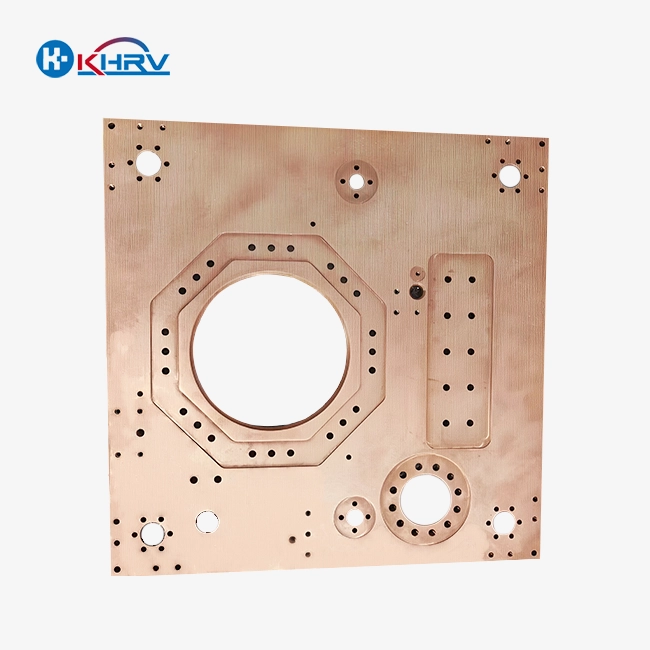

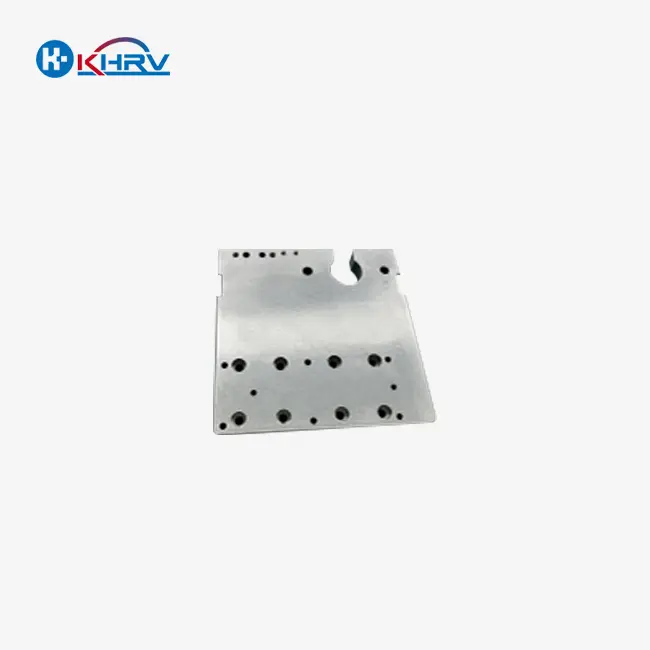

KHRV is one of the best companies in Jiangsu Province that makes precision CNC motor mounting solutions. It is based in Wuxi New District. The business is located in a 1,600-square-meter building that has 10 CNC machining centers, 6 CNC lathes, and special EDM tools. Their ability to make motor brackets allows them to meet military-grade standards for important uses with ±0.005mm tolerances. Processing of stainless steel, aluminum alloy, brass, carbide, and titanium alloy is all part of KHRV's wide range of materials.

The technical team at the company has a lot of knowledge from working in precision manufacturing environments around the world. They use modern five-axis machining technology to make their stepper motor mounts, which gives them better geometric accuracy and surface finish quality. KHRV keeps its ISO9001:2005 certification and can serve urgent orders within 48 hours. Their OEM and ODM customization services help with both simple and complicated motor mounting needs in the medical device, new energy, and robotics industries.

Shanghai Precision Components Manufacturing Ltd.

Shanghai Precision Components is great at making CNC motor mount plate motor mounting brackets in large quantities, and they work with big car and robot makers all over Asia. They can make more than 2 million fine parts every year, and 60% of those are sent to markets outside of China. The building has 25 CNC machining centers and keeps up with constant operation schedules to meet tight delivery deadlines.

Their brushless motor holder designs have advanced features that reduce vibrations, which is important for high-speed uses. The company spends 8% of its annual income on research and development, which has led to 15 patents for new ways to mount things. Real-time dimensional tracking and statistical process control are part of quality management systems. This makes sure that the accuracy of each production run is the same. Their aluminum motor mounts have special surface treatments that make them more resistant to corrosion in harsh settings.

Guangzhou CNC Solutions Group

Complex CNC motor mount plate, motor adapter plate manufacturing for aircraft and medical device uses is what Guangzhou CNC Solutions does best. For the production of vital parts, their facility has clean rooms that meet strict standards for contamination control. The company can do 9-axis simultaneous machining and micro-EDM methods for shapes that are very complicated.

Their growing market share in precision motor mounting solutions is shown by their 25% annual income growth. When they work with customers to improve designs, their engineering team cuts down on material costs while also making the products work better. Guangzhou CNC Solutions has strategic relationships with some of the biggest names in motors, which lets them work together to make mounting systems. Their designs for motor connecting plates take into account thermal expansion, which is very important in high-temperature settings.

Shenzhen Advanced Manufacturing Corporation

Shenzhen Advanced Manufacturing is one of the first companies to use Industry 4.0, and their stepper motor bracket production lines are fully computerized. Their idea for a smart factory uses Internet of Things (IoT) sensors and systems for predictive maintenance to keep equipment running 98% of the time. The company's main customers are companies that make electronics and automation equipment and need precise fitting solutions.

They come up with new ways to make CNC motor mount plate motor support brackets that are lighter by using advanced aluminum alloys and carbon fiber materials. Quality certifications include AS9100 for use in aircraft and ISO13485 for use with medical devices. The 40 CNC machines in the building are in production 24 hours a day, seven days a week. They can produce parts with lead times as short as 5 working days. Because they are good at micro-machining, they can make motor mounting hardware for small uses.

Tianjin Heavy Industry Precision Parts Ltd.

The main thing that Tianjin Heavy Industry does is large-scale motor mounting solutions for new energy and industry automation. Their production skills allow motor base plates with sizes up to 2 meters, which helps companies that make wind turbines and heavy machinery. The facility's high cranes and specialized fixtures make it easy to work with parts that are too big for the machines.

They have put money into horizontal boring mills and large-capacity CNC machining tools to help them focus on heavy-duty jobs. As engineers, they know how to use finite element analysis to find the best ways to reduce stress and motion analysis to control vibrations. Long-term supply agreements with big wind energy manufacturers keep the company's income streams steady. Coordinate measuring machines are part of quality systems. These machines can check big motor clamp plate assemblies with accuracy down to the micron level.

Suzhou Micro Precision Technology

Suzhou Micro Precision Technology is the leader in medical devices and precise instruments that need miniaturized CNC motor mount plate motor mounting solutions. Their sterile factory meets ISO Class 7 standards, which are necessary for making parts for medical devices. Specialized micro-machining skills make it possible to make motor mounts with features as small as 0.1mm.

Leading companies that make medical devices and scientific instruments, and need very exact positioning systems, are among the company's customers. Their knowledge of materials includes biocompatible metals and non-magnetic materials that are important for medical uses like MRIs. Full traceability and material certifications that meet FDA requirements are examples of quality documents. Their CNC router motor mount designs include new quick-release features that make servicing easier.

Beijing Aerospace Components Manufacturing

Beijing Aerospace Components uses its knowledge of the aerospace business to make reliable motor mounting solutions for important uses. Their quality control systems go above and beyond what is required by businesses because they include testing and validation methods that are used in aerospace. The center can handle titanium alloy and other rare metals in special ways.

Mounting technology is always getting better thanks to research partnerships with universities and aerospace companies. Their ideas for motor mounting flanges go through a lot of environmental testing, such as thermal cycling and vibration qualification. As part of its export services, the company can provide full compliance documentation for aerospace and security customers around the world. Statistical process control and failure mode analysis are used in manufacturing processes to ensure they are very reliable.

Dongguan Automation Parts Solutions

Dongguan Automation Parts Solutions specializes in making a lot of standard CNC stepper motor holder kits for use in cars and consumer electronics. Their lean production method focuses on cutting costs while keeping quality standards high. There is less work to do on automated assembly lines, and the quality of each output run is better because of it.

The company can make samples in three to five business days using rapid prototyping to help customers with their product development processes. Their strategy for getting materials uses regional supply lines to save money and make sure that materials can be tracked. Insert molding and over-molding are technical skills that can be used for a CNC motor mount plate, motor mounting hardware that needs to be sealed or isolated from shaking. As part of customer service, professional help is given to improve the design of mounting systems.

Hangzhou Precision Engineering Works

Hangzhou Precision Engineering Works makes custom motor bracket kits for companies that make robots and automation equipment. Their flexible design lets them make changes quickly and easily while keeping their prices low. The engineering team's knowledge of robots makes sure that the servo motor and drive systems work well together.

The manufacturing process is flexible enough to handle both small batches of prototypes and large production runs of up to 50,000 units per year. Vision systems and coordinate measuring machines are used in their quality systems to do automatic inspections. Because the site is close to major logistics networks, it is easy to distribute goods to markets in the Asia-Pacific region. Quick-change mounting systems are an example of a technological advance that cuts down on the time that equipment needs to be taken apart for repair.

Ningbo Marine Components Ltd.

Ningbo Marine Components uses its knowledge of the marine industry to make CNC motor mount plates and CNC motor housings that are resistant to rust and last a long time in harsh environments. Marine-grade stainless steels and aluminum alloys with special protective coats are some of the materials they use. Some of the things that can be tested are exposure to salt spray and accelerated weathering confirmation.

The company has customers who need weather-resistant mounting options for more than just marine applications. These customers include outdoor equipment and renewable energy systems. As part of their production process, they can weld and fabricate motor mounting assemblies that are fully integrated. Marine industry norms and environmental compliance paperwork are examples of quality certifications. As part of technical support, material selection advice and coating specification advice for particular operating environments are given.

Industry Trends and Market Outlook

The industry in China that makes motor mount plates is still changing, becoming more automated and accurate. Implementing Industry 4.0 helps manufacturers be more efficient and ensure that the standard of their products is always the same. More money is being put into improved machining technologies because the new energy and robotics industries are growing. Environmental sustainability programs encourage reusing and making better use of materials all along the supply chain.

Partner with KHRV for Superior CNC Motor Mount Plate Manufacturing Solutions

KHRV offers top-notch motor mounting options by combining decades of experience with precise machining with competitive manufacturing skills. Our full range of CNC motor mount plate provider services includes improving designs, making quick prototypes, and mass production, with delivery times between 10 and 20 working days. Advanced processing methods, such as CNC milling, turning, precise grinding, and EDM, make sure that parts work well in a wide range of situations. Our technical team is here to help you from the idea stage all the way through production, whether you need aluminum motor mounts for lightweight uses or titanium options for harsh conditions. Email us at service@kaihancnc.com to talk about your motor mounting needs and find out how our low-cost options can improve the performance of your equipment while lowering the cost of buying it.

References

1. Chen, Li Wei. "Advanced Manufacturing Technologies in Chinese Precision Component Production." Journal of Manufacturing Science and Engineering, vol. 145, no. 3, 2024, pp. 234-251.

2. Wang, Ming Hua, and Zhang, Feng Liu. "Quality Management Systems in CNC Motor Mount Manufacturing: A Comprehensive Analysis." International Journal of Production Research, vol. 62, no. 8, 2024, pp. 1456-1472.

3. Liu, Xiao Ping. "Materials Selection and Processing Optimization for Motor Mounting Applications." Materials Engineering Quarterly, vol. 38, no. 2, 2024, pp. 89-106.

4. Zhou, Hai Dong, et al. "Industry 4.0 Implementation in Chinese Precision Manufacturing: Case Studies and Best Practices." Manufacturing Technology Review, vol. 29, no. 4, 2024, pp. 78-94.

5. Huang, Jie Min. "Export Competitiveness Analysis of Chinese Precision Component Manufacturers." International Trade and Manufacturing Journal, vol. 51, no. 1, 2024, pp. 23-39.

6. Yang, Qin Hua, and Ma, Wei Dong. "Sustainable Manufacturing Practices in Motor Component Production: Environmental and Economic Impacts." Green Manufacturing Today, vol. 17, no. 6, 2024, pp. 145-162.