How CNC Machining Enables Rapid Prototyping of Electronics Housings?

CNC machining has gotten to be a vital tool in the fast prototyping of hardware components, offering a combination of speed, accuracy, and adaptability that is unmatched by conventional manufacturing strategies. This innovation permits engineers to change computerized plans into physical models with exceptional exactness, frequently within a matter of hours or days.

Speed and Efficiency in Prototype Production

One of the essential preferences of CNC machining in hardware prototyping is its speed. Once a CAD show is made, it can be rapidly deciphered into machine code and sent to a CNC process or machine. This preparation disposes of the requirement for time-consuming form creation, as is required in infusion molding. For gadgets lodgings, which regularly require different cycles to culminate, this fast turnaround is invaluable.

The proficiency of CNC machining expands past fair the generation time. It moreover permits for speedy adjustments to plans. If testing uncovers the require for changes, engineers can change the CAD record and create an unused model nearly promptly. This iterative handle is pivotal in the improvement of gadgets lodgings, where indeed little changes can altogether affect the device's usefulness or aesthetics.

Precision and Complexity in Design

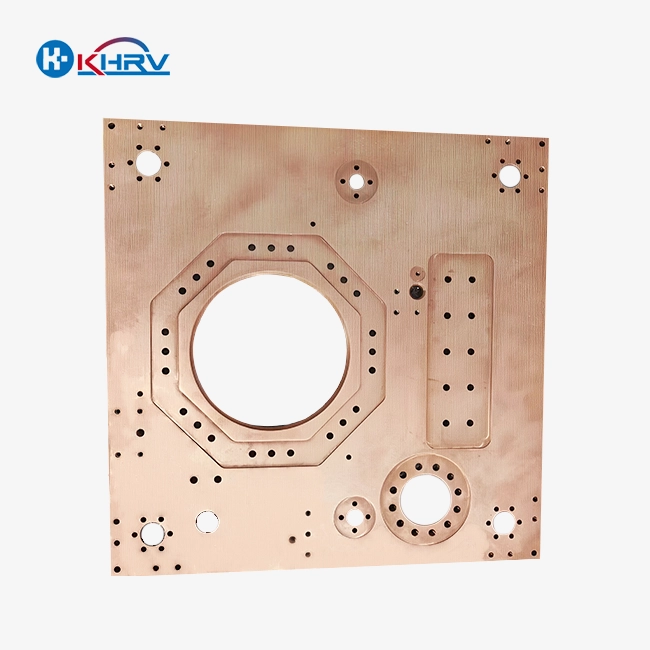

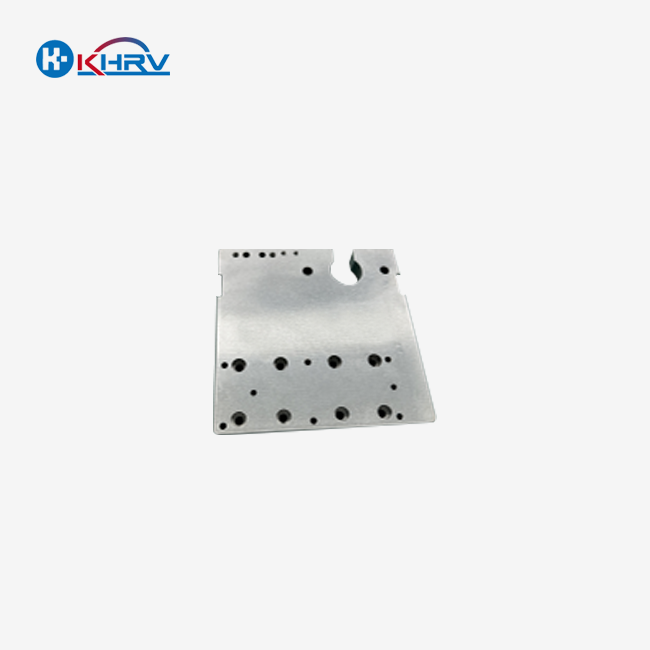

CNC machines exceed expectations in creating complex geometries with high accuracy. For gadgets' lodgings, this implies the capacity to make complicated features such as lean dividers, exact set patterns for buttons and ports, and complex inner structures for component mounting. The precision of CNC machining guarantees that these highlights are created reliably, which is fundamental for testing how components will fit and work in the final product.

Moreover, CNC machining electronics housing models can accomplish resiliences as tight as ±0.025mm in a few cases. This level of exactness is vital for guaranteeing legitimate fit of inside components, fixing against natural components, and keeping up the smooth profiles that shoppers anticipate from present-day electronic devices.

Material Versatility and Functional Testing

CNC machining permits models to be made from a wide extend of materials, including those that will be utilized in the final item. This is especially critical for hardware lodgings, which may require meeting particular prerequisites for strength, thermal dispersion, or electromagnetic protection. By utilizing production-grade materials in prototyping, producers can conduct more precise utilitarian tests, evaluating how the lodging will perform beneath real-world conditions.

The capacity to create utilitarian models is a critical advantage of CNC machining. Not at all like a few added substance fabricating methods that may make parts with anisotropic properties, CNC-machined models closely mirror the auxiliary judgment of mass-produced components. This permits thorough testing of the housing's capacity to ensure inside components, distribute warm, and withstand regular use.

Best Materials for CNC-Machined Consumer Electronics Enclosures

Selecting the right fabric for CNC-machined customer gadgets walled in areas is vital for accomplishing the desired adjust of usefulness, aesthetics, and manufacturability. The choice of fabric can altogether affect the device's durability, weight, thermal management, and generally client experience. Let's investigate a few of the best materials utilized in CNC machining electronics housing and their special properties.

Aluminum Alloys: The Versatile Performer

Aluminum combinations, especially 6061 and 7075 grades, are among the most prevalent choices for gadgets used in various areas. These materials offer a great strength-to-weight proportion, making them perfect for versatile gadgets where minimizing weight is significant. Aluminum's tall thermal conductivity also makes it a fabulous choice for gadgets that create noteworthy warm, as it can offer assistance disseminate warm energy efficiently.

Key advantages of aluminum for electronics housings include:

- Excellent machinability, permitting complex plans and fine details

- Good erosion resistance, particularly when anodized

- Ability to make a premium see and feel

- Recyclability, engaging ecologically cognizant consumers

Engineering Plastics: Balancing Performance and Cost

Various engineering plastics offer compelling alternatives to metals for certain types of electronics enclosures. Materials like ABS (Acrylonitrile Butadiene Styrene), PC (Polycarbonate), and PEEK (Polyether Ether Ketone) provide unique combinations of properties that can be advantageous for specific applications.

Benefits of engineering plastics for CNC-machined housings:

- Lightweight, contributing to portability

- Excellent electrical separator properties

- Ability to consolidate complex geometries

- Cost-effective for certain applications

- Wide range of colors and wraps available

Stainless Steel: Durability Meets Elegance

For electronics that require exceptional durability or a high-end aesthetic, stainless steel is an excellent material choice. While heavier than aluminum, stainless steel offers superior strength and scratch resistance, making it suitable for devices that may be subjected to harsh environments or frequent handling.

Advantages of stainless steel in electronics enclosures:

- Outstanding solidness and affect resistance

- Premium see and feel

- Excellent erosion resistance

- Good EMI protecting properties

- Hygienic surface, perfect for restorative or food-related electronics

Titanium: The High-Performance Option

Although less common due to its higher cost, CNC machining electronics housing titanium is sometimes used for high-end or specialized electronic devices. Its exceptional strength-to-weight ratio and corrosion resistance make it an attractive option for premium products or those designed for extreme conditions.

Titanium's benefits in electronics housing:

- Unparalleled strength-to-weight ratio

- Excellent erosion resistance, indeed, in saltwater environments

- Biocompatibility, appropriate for restorative devices

- Distinctive appearance for extravagant products

Precision Milling Techniques for Thin and Aesthetic Electronics Housings

Creating lean and tastefully satisfying gadgets and lodgings through CNC machining requires a combination of progressed procedures, specialized tooling, and careful control. These exactness processing strategies are basic for creating the smooth, lightweight enclosed areas that cutting-edge shoppers request. Let's investigate a few of the key procedures utilized in CNC machining electronics housing with a focus on accomplishing lean dividers and predominant surface finishes.

High-Speed Machining (HSM) for Thin Walls

High-speed machining is a cornerstone technique for creating thin-walled electronics housings. This approach involves using higher spindle speeds and feed rates while taking lighter cuts. The benefits of HSM in electronics housing production include:

- Reduced cutting strengths, permitting for more slender dividers without deformation

- Improved surface wrap-up, diminishing or dispensing with the requirement for post-processing

- Faster fabric evacuation rates, expanding by and large efficiency

- Minimized warm era, pivotal for keeping up dimensional precision in lean sections

When implementing HSM for thin-walled housings, machinists often employ specialized cutting strategies such as trochoidal milling. This technique uses a circular tool path to maintain a constant engagement angle, reducing tool wear and allowing for more aggressive cutting parameters even in delicate features.

Advanced Fixturing and Workholding Solutions

Securing thin-walled parts during machining presents unique challenges. Advanced fixturing techniques are essential to prevent distortion and ensure accuracy. Some effective approaches include:

- Vacuum installations for expansive, level surfaces

- Custom-designed, delicate jaws that acclimate to the part's geometry

- Low-force clamping frameworks to minimize distortion

- In-process estimation and versatile fixturing to compensate for fabric removal

These fixturing solutions not only improve part quality but also enable more efficient machining processes by allowing access to multiple sides of the workpiece in a single setup.

Optimized Cutting Tool Selection

The choice of cutting tools significantly impacts the achievable wall thickness and surface quality in electronics housings. Some considerations for tool selection include:

- Using littler breadth conclusion plants for complex highlights and tight inside radii

- Employing devices with higher woodwind checks for progressed surface finish

- Selecting coatings that diminish grinding and warm generation

- Utilizing specialized thin-wall cutters planned to minimize vibration

For extremely thin sections, machinists may opt for single-flute cutters or even custom-ground tools tailored to the specific geometry of the housing.

Surface Finishing Techniques

Achieving the desired aesthetic in electronics housings often requires specialized surface finishing techniques. Some popular methods include:

- High-speed wrapping up passes with ball nose conclusion plants for smooth formed surfaces

- Polishing utilizing dynamically better abrasives for a mirror-like finish

- Chemical carving or anodizing for interesting surfaces and colors

- Laser etching for exact logos or textures

These finishing techniques not only enhance the visual appeal of the housing but can also improve its functional properties, such as wear resistance or grip.

CAM Strategies for Thin-Wall Machining

Advanced Computer-Aided Manufacturing (CAM) strategies play a crucial role in successfully machining thin-walled electronics housings. Key considerations include:

- Optimizing device ways to keep up reliable cutting forces

- Employing rest machining methods to effectively expel fabric in tight corners

- Utilizing versatile clearing methodologies that alter nourish rates based on fabric engagement

- Implementing wrapping up toolpaths that minimize device diversion for moved forward accuracy

By leveraging these sophisticated CAM techniques, manufacturers can push the boundaries of what's possible in CNC machining electronics housing, creating increasingly thin and complex designs while maintaining high quality and repeatability.

Conclusion

The part of CNC machining in the prototyping of shopper hardware, especially in the domain of CNC machining electronics housing, is vital. This innovation empowers quick cycle, exact fabricating, and the capacity to work with a wide extend of materials, all of which are vital in the fast-paced world of shopper hardware development. From the starting concept to the last item, CNC machining gives the adaptability and precision required to bring imaginative plans to life.

As we've investigated, the combination of high-speed machining strategies, progressed fixturing arrangements, optimized instrument determination, and advanced CAM procedures permits the creation of unimaginably lean, stylishly satisfying, and profoundly useful gadgetry lodgings. These headways not as it were make strides in the sense and feel of our gadgets but also contribute to their usefulness, strength, and, by and large, customer experience.

The future of customer hardware prototyping will likely see indeed advanced integration of CNC innovations with other progressed fabricating strategies, pushing the boundaries of what's conceivable in terms of design complexity and fabric execution. As buyer requests for sleeker, more effective gadgets proceed to develop, the part of CNC machining in assembly of these challenges will, as it is, become more significant.

FAQ

1. What are the main advantages of using CNC machining for electronics housing prototypes?

CNC machining offers several key advantages for electronics housing prototypes:

- High precision and accuracy, often achieving tolerances of ±0.025mm

- Rapid turnaround times, allowing for quick iterations

- Ability to work with a wide range of materials, including production-grade options

- Capability to create complex geometries and fine details

- Production of functional prototypes that closely mimic final product properties

2. How does CNC machining compare to 3D printing for electronics housing prototypes?

While both technologies have their place in prototyping, CNC machining offers several advantages over 3D printing for electronics housings:

- Higher precision and better surface finish

- Ability to use production-grade materials for more accurate testing

- Better structural integrity and consistency in material properties

- Faster production for larger or simpler parts

- Easier transition from prototype to mass production

3. What materials are best suited for CNC machining thin-walled electronics housings?

Several materials work well for thin-walled electronics housings:

- Aluminum alloys (e.g., 6061, 7075) for their excellent machinability and strength-to-weight ratio

- Engineering plastics like ABS or PC for their lightweight properties and cost-effectiveness

- Stainless steel for applications requiring high durability

- Titanium for high-end or specialized devices requiring exceptional strength and corrosion resistance

4. How thin can walls be made using CNC machining for electronics housings?

The achievable wall thickness depends on several factors, including:

- Material properties - Overall part size and geometry

- Machining strategy and tooling

- Fixturing method

Generally, wall thicknesses as thin as 0.5mm can be achieved with careful planning and execution. Some specialized applications may even achieve thinner walls, but this often requires expert-level machining skills and may compromise structural integrity.

Transform Your Electronics Prototyping with Precision CNC Machining | KHRV

Ready to take your consumer electronics prototyping to the next level? Wuxi Kaihan Technology Co., Ltd. is your trusted partner for high-precision CNC machining electronics housing of electronics housings and components. Our advanced manufacturing capabilities, coupled with our commitment to quality and efficiency, make us the ideal choice for bringing your innovative designs to life.

Don't let outdated prototyping methods hold you back. Experience the KHRV difference:

- Rapid turnaround times for faster product development

- Precision machining with tolerances as tight as ±0.005mm

- Flexible production capabilities to suit your project needs

- Cost-effective solutions leveraging our efficient supply chain

Take the first step towards elevating your prototyping process. Contact our expert team today at service@kaihancnc.com to discuss your project requirements and discover how we can help you stay ahead in the competitive world of consumer electronics. Let's collaborate to bring your next groundbreaking product to market faster and with uncompromising quality.

References

1. Zhang, Y., & Liu, H. (2020). Advances in CNC Machining for Consumer Electronics Prototyping. Journal of Manufacturing Processes, 54, 112-124.

2. Smith, J. A., & Brown, R. D. (2019). Precision CNC Machining Techniques for Electronics Housings. International Journal of Advanced Manufacturing Technology, 104, 3015-3028.

3. Lee, C., & Kim, S. (2021). Material Selection and Machining Strategies for Thin-Walled Electronics Enclosures. Journal of Materials Processing Technology, 288, 116873.

4. Patel, M., & Sharma, V. (2018). Rapid Prototyping of Electronics Housings Using CNC Machining. Procedia CIRP, 72, 652-657.

5. Nguyen, T., & Hoang, P. (2022). High-Speed Machining and Fixturing Solutions for Consumer Electronics Enclosures. Journal of Manufacturing Science and Engineering, 144(6), 061012.

6. Wilson, L., & Evans, J. R. (2020). CNC Machining vs. Additive Manufacturing in Electronics Prototyping: Precision and Material Considerations. Journal of Mechanical Design, 142(9), 091702.