- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

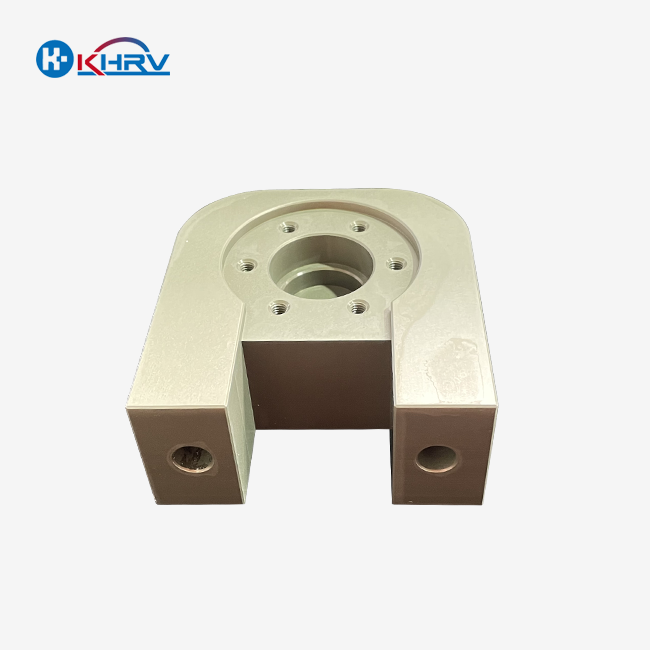

65HRC Milling Cutter manufacturer

Why Choose 65HRC Milling Cutter for Tough Materials

Built for Extreme Hardness Hardened steel and titanium are machined using 65HRC milling cutters. These carbide-based tools stay sharp under tremendous loads.

Precision Engineering for Perfect Results Micron-level precision is ensured by rigorous quality inspections on every cutter.

This precision reduces vibration and ensures smooth finishing for aerospace and automotive products.

Versatile Industrial Applications These cutters thrive in durable, precise sectors like mold-making and gear production.

They can withstand 65HRC hardness, making them perfect for high-temperature applications.

Global manufacturers trust us Longer tool life and lower replacement costs are achieved via advanced coatings and geometry.

Global factories depend on these high-performance tools for constant production.

Precision 65HRC milling cutters for high-hardness materials.

Global producers rely durable carbide industrial tools.

These tools are designed for tough industries to endure and cut precisely.

Wuxi Kaihan Technology: Precision Engineers Jiangsu-based

Wuxi Kaihan Technology has provided innovative manufacturing solutions since 2011. With 15 years of experience and lean manufacturing, the firm makes OEM precision components and semi-finished multi-material products.

Global industry leaders trust Top Singaporean engineers invest 36% of resources in R&D, resulting in 22 patents.

Affordable CNC tools and custom machining satisfy quality standards.

Innovation Meets Efficiency Complex geometries are handled in advanced aerospace, automotive, and electronics workshops.

High-volume orders function consistently with multi-stage quality checks.

Manufacturing Sustainability Intelligent material use saves waste, and energy-efficient operations meet worldwide environmental requirements.

Partnerships value stability above short-term advantages.

Precision, durability, and industrial process integration are evident in every component.

Precision-Made Tools for Hard Machining Hardened

steels, titanium alloys, and sophisticated composites are too hard for common tools. A reputable 65HRC Milling Cutter manufacturer, Wuxi Kaihan Technology Co., Ltd.

provides designed products with great durability and precision.

Aerospace components, automotive dies, and industrial mold fabrication require hardness, heat resistance, and tool durability.

Our cutters excel in these applications.

What distinguishes our 65HRC Milling Cutters?

Even under harsh cutting circumstances, advanced coatings and substrates reduce wear.

These tools keep sharp edges longer, saving downtime and tool replacement costs for complicated geometries or high-volume manufacturing.

We also provide bespoke engineering to customize tool geometries, coatings, and edge preparations for your material or operation.

Key technical specs: 65HRC-compatible hardness AlTiN, TiSiN, or hybrid coatings 3–25mm diameter (custom sizes available).

Straight, Weldon, or HSK shanks Ideal for HRC 45-65 steels, nickel alloys, and ceramics The correct tool is crucial for dependable performance in the toughest situations.

FAQs

1. What materials can your 65HRC Milling Cutter handle?

Our cutters are designed for hardened steel, titanium alloys, and superalloys. As a reputable 65HRC Milling Cutter manufacturer, we employ superior carbide substrates and innovative heat treatment for aerospace, automotive, and mold-making stability.2. How durable are these cutters compared to others?

Ultra-fine grain carbide cores and multi-layer coatings make our 65HRC Milling Cutters survive 3-5x longer in severe machining. Our factory's rigorous quality inspections reduce wear even during high-speed operations.3. What coating advantages do your cutters have?

Specialized AlTiN or TiSiN coatings reduce friction by 40% and withstand 1,000°C. Energy and medical device manufacturers benefit from smoother cuts, fewer tool changes, and cheaper production costs.4. Why chose your 65HRC Milling Cutter manufacturer?

We provide customizable customisation and 15+ years of precision tooling R&D. ISO 9001-certified manufacturing customizes flute counts, shapes, and coatings for each project.5. Do you offer technical and buying advice?

Absolutely! Free machine parameter optimization (speed, feed, depth) by our engineers. Quotes, wholesale savings, and global shipping are available at [Company Website] or support@kaihantech.com.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email