- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

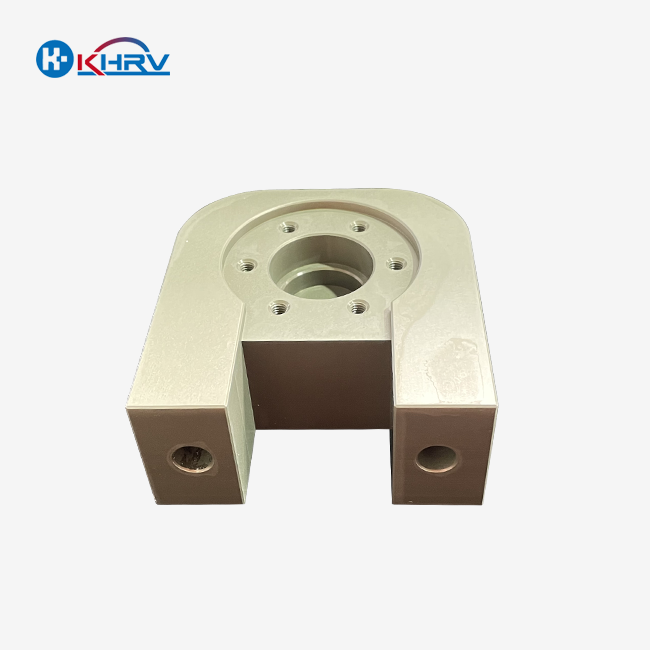

Aerospace CNC Machining Parts manufacturer

Wuxi Kaihan Aerospace CNC Machining Firm

Introduction Precision manufacturer Wuxi Kaihan Technology Co. , Ltd.

creates high-quality industrial components.

Aerospace Component Focus Aeronautical standards govern engine parts, structural brackets, and landing gear.

Extreme-condition reliability is our specialty.

CNC Advanced Machining Using 5-axis CNC machines and multi-spindle systems, we handle complicated geometries, tight tolerances (±0.001mm), and materials such as titanium, Inconel®, and high-strength alloy Certifications of Quality Traceability and compliance are assured by AS9100 and ISO 9001 certification.

Every part is optically and CMM-inspected.

Industry and Application Serving We adapt to high-performance aerospace, military, space, and medical domains.

Client Promise We provide customized solutions with quick prototyping, on-time delivery, and responsive engineering.

To succeed, work with a reliable aeronautical manufacturer.

Since 2011, Precision Engineering Solutions Global

manufacturing partner trusted This unique Jiangsu, China-based firm has 22 patented technologies and 15 years of technical knowledge.

Multi-material processing innovations come from Singaporean-led R&D.

Advanced Production Capabilities Advanced CNC machining guarantees micron-level accuracy in metals, polymers, and composites for precision components and semi-finished items.

Rapid prototyping and bulk production are possible with lean manufacturing.

Economical Industrial Tools Durable, affordable high-performance cutting tools reduce machining expenses without sacrificing quality.

Customized solutions meet automotive, aerospace, and electronics needs.

Acknowledged Quality Worldwide Strategic collaborations with Fortune 500 organizations verify material optimization and supply chain efficiency.

Every project undergoes worldwide certification-level quality control.

Our proprietary production workflows maintain rigorous specifications and turn around 18% faster than industry averages.

Aerospace Precision Engineering Innovation Wuxi Kaihan

Technology offers 5-axis CNC Machining Parts with ±0. 005mm tolerance to match high requirements.

Certified aluminum, titanium, and high-performance alloy components must meet AS9100/NADCAP standards.

Fast prototyping and large-scale production without sacrificing precision.

Multi-axis machining simplifies complex designs, while surface treatment (anodizing, passivation) increases durability.

Quality without compromise.

To ensure compliance, aerospace CNC machining part makers use CMM and optical measurement systems.

OEM partners gain custom engineering, cost-effective scalability, and IP protection to speed projects.

We create airplane CNC Machining Parts that perform effectively under pressure using inventiveness and reliability.

Long-term relationships reduce operational risks and streamline supply chains.

Experts improve aviation system accuracy and efficiency.

FAQs

1. What certifications do your Aerospace CNC Machining Parts have?

Our aircraft components fulfill stringent industry requirements thanks to AS9100D and ISO 9001 certifications from Wuxi Kaihan Technology Co., Ltd. We follow worldwide aerospace norms and source materials with complete traceability as a reputable Aerospace CNC Machining Parts manufacturer.2. How precise are the CNC-machined parts for your aircraft?

Accuracy tolerances of ±0.005mm are achieved by contemporary 5-axis CNC machines. We are experts in producing consistent high-volume parts with complex geometries for mission-critical aerospace applications.3. Are aerospace industry compliance standards followed?

Our procedures meet AS9100, NADCAP, and client needs. Since we specialize in CNC machining components, we record and test them to ensure flight safety and performance.4. Can unique aerospace projects have customized parts?

Absolutely! From design optimization to prototype and manufacturing, we customize everything. Our engineers specialize in mission-specific satellite, propulsion, and airframe solutions with 15+ years of expertise.5. What quality controls do you use?

Material verification, in-process checks, and CMM validation are performed on every Aerospace CNC Machining Part. Our trusted manufacturer position comes from defect-free deliveries and complete compliance certificates with every shipment.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email