- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

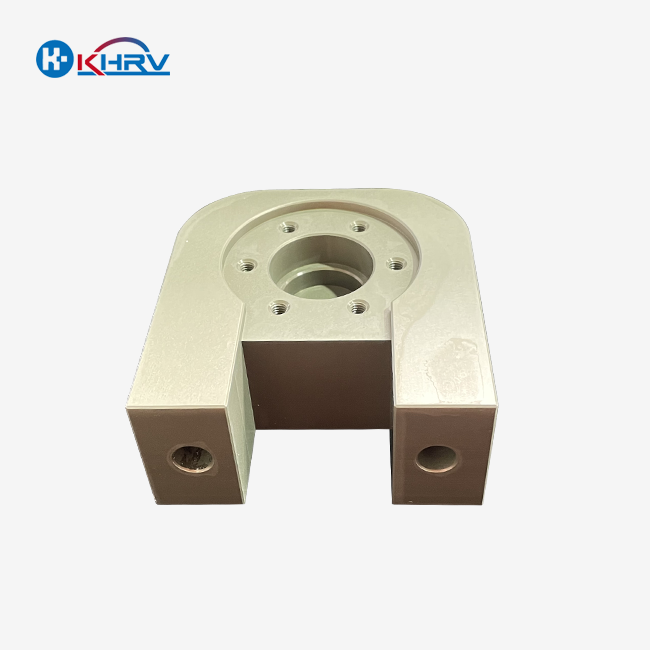

70HRC Milling Cutter manufacturer

Precision 70HRC Milling Cutters for Industrial

Excellence Wuxi Kaihan Technology Co. , Ltd.

designs ultra-durable 70HRC Milling Cutters for the hardest machining tasks.

We use innovative carbide compositions and rigorous heat treatment to make tools that resist wear, preserve sharpness, and perform well in high-stress applications as a trusted manufacturer.

The patented surface coatings on our cutters increase heat resistance and minimize friction, extending tool life in aerospace, automotive, and mold-making applications.

ISO-certified quality inspections provide consistency for precision-critical operations on every product.

Need customized solutions?

An innovative R&D team supports our customisable geometries and coatings for individual project needs.

We work with industry leaders because to our durability and technological competence, serving over 30 countries.

Our worldwide verified hardened material tools satisfy engineers seeking dependable, high-performance equipment.

Precision Manufacturing Specialists Wuxi Kaihan Technology

Established Innovation Leader Established in 2011 in Jiangsu, China, we offer 15+ years of experience and cutting-edge R&D.

Top Singaporeans make up 36% of our staff, which advances material science and industrial technology.

Solutions for Global Industries Custom precision parts manufacturer, we provide semi-finished components for metals, plastics, and composites.

Our affordable CNC tools speed manufacturing while meeting quality standards.

Industry pioneers trust With 22 patented inventions and lean manufacturing techniques, we improve operations to save waste and speed up time.

Clients worldwide trust our technical expertise to tackle complicated engineering problems.

All projects benefit from rigorous testing and adaptable design.

Small batch and large-volume orders are scalable with our modular approach.

Advanced automation ensures manufacturing cycle consistency.

Hardened Material Machining Precision Solutions Tools

with exceptional durability and precision are needed for hardened steels and titanium alloys. Wuxi Kaihan Technology Co., Ltd.

is a reputed 70HRC Milling Cutter manufacturer that designs high-performance cutting tools for harsh situations.

Why pick our 70HRC Milling Cutters?

Our proprietary coatings improve wear resistance and save downtime.

Optimized Geometry: Precision-ground edges make finishes smooth and reduce vibration.

Hardened steels (HRC 50-70), superalloys, and composites are compatible.

Industry-Proven: Useful for aircraft, automotive, and energy equipment.

We have over a decade of R&D experience tackling complicated machining problems as a 70HRC Milling Cutter maker.

When shaping delicate aerospace components or refining high-wear automobile tools, our cutters function consistently under extreme loads.

Wuxi Kaihan's accuracy and dependability solutions help manufacturers reduce cycle times and operational expenses.

Discover how our 70HRC Milling Cutters may improve your output.

The proper tool turns obstacles into opportunities—discover the difference with an innovative, quality partner.

FAQs

1. What makes 70HRC Milling Cutter suited for ultra-hard materials?

Milling Cutters mill ceramics, titanium alloys, and hardened steel at 70 Rockwell C. AlTiN coatings cool and precision-ground edges cut cleanly. Wuxi Kaihan Technology Co., Ltd. improved cutter geometry for durability.2. Which industries usually employ 70HRC Milling Cutters?

These cutters are suited for aerospace (turbine components), automotive (gears/molds), energy (drilling tools), and precision engineering. The recognized 70HRC Milling Cutter maker Wuxi Kaihan tailors solutions for high-stress applications to provide stability in difficult settings.3. How can I find a reputable 70HRC Milling Cutter manufacturer?

Find carbide tooling knowledge, ISO-certified manufacturing, and performance statistics. Wuxi Kaihan Technology Co., Ltd. customizes tools for certain materials. Strict quality inspections (hardness, edge consistency). Technical assistance for cutting parameter optimization.4. Can these cutters machine dry and coolant?

Yes! Our 70HRC Milling Cutters include heat-resistant coatings for dry cutting or low-lubrication. Flexibility saves operational expenses and matches different workshop situations.5. Why buy 70HRC Milling Cutter from Wuxi Kaihan?

With 15+ years of precision tool manufacture, we combine cutting-edge R&D and tight quality control. Our durable, low-downtime equipment and consistent finishes make us a top choice for industrial-grade milling solutions globally.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email