- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

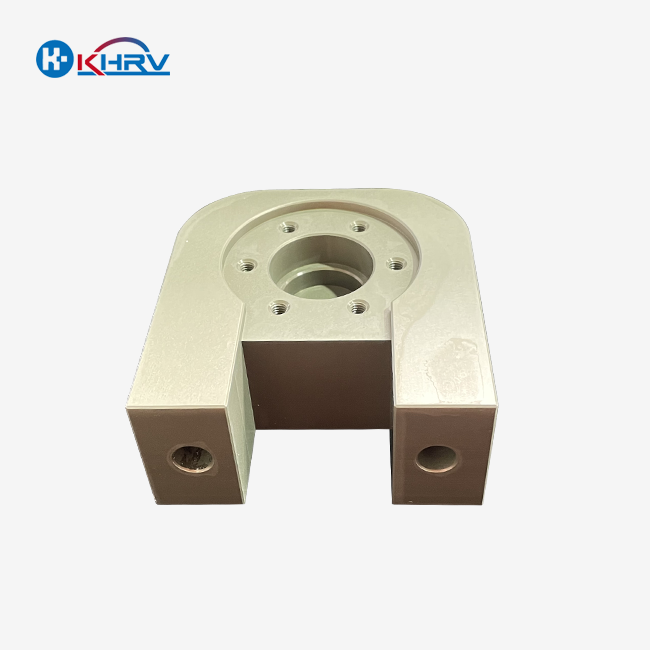

Mechanical Parts Bearing Seat manufacturer

Industrial Excellence with Precision Engineered Bearing

Seats Reliable machinery relies on precision-built **Mechanical Parts Bearing Seats**. We manufacture ISO-certified bearing seats that can handle heavy loads, vibrations, and tough working conditions at Wuxi Kaihan Technology Co., Ltd.

Built for Demanding Applications Advanced materials and strict tolerances make our bearing seats compatible with rotating assemblies.

These components reduce wear and improve operations in mining and agricultural machines.

We prioritize customized solutions and global standards in our production process.

We meet your specific needs without compromising durability, whether you need custom measurements, coatings, or quick prototyping.

Industry leaders trust Every bearing seat is quality-checked by precise engineers with decades of experience.

Our ISO-certified facilities provide consistency, and our technical staff supports complicated projects end-to-end.

High-performance **Mechanical Parts Bearing Seat** components are a commitment to operational lifetime.

Since 2011, Precision Engineering Solutions Wuxi

Kaihan Technology in Jiangsu, China, innovates and manufactures. The team has provided high-quality precision components and semi-finished products to numerous sectors for over a decade.

Innovation-backed expertise Solutions promote efficiency and reliability with 22 patents and a 36% engineering-focused R&D workforce.

Multi-material processing processes are optimized by Singaporean technical professionals' worldwide understanding.

Excellence in Lean Manufacturing Lean manufacturing techniques reduce waste and maintain aerospace, automotive, and industrial tolerances.

Long-term operational expenses are reduced by custom CNC tooling's price and performance.

Global partners trust Flexible OEM services meet customer needs from prototyping to volume manufacturing.

Fortune 500 manufacturers seeking scalable precision solutions recognize advanced quality control for consistency.

Every component combines cutting-edge design and rigorous testing to optimize supply chains without compromising quality.

Reliable Bearing Solutions through Precision Engineering

Wuxi Kaihan Technology Co. , Ltd.

designs and manufactures high-performance Mechanical Parts Bearing Seats for many industries.

We produce components that assure stability, decrease wear, and increase equipment lifespan as a trusted **manufacturer** using modern engineering and strict quality control.

Why Choose Our Bearing Seats?

- Technical Expertise: Tight tolerances for efficient load distribution in precision-machined seats.

Customization: Fit designs to specific gear or materials.

Quality Assurance: Stress testing, material certification, and surface finish inspection are done on every product.

Excellent for automotive, aircraft, mining, and energy.

CNC machining, heat treatment, and anti-corrosion coatings increase longevity in our production process.

Our Mechanical Parts Bearing Seats, whether conventional or customized, are designed to work with your systems.

We provide flexible order sizes and ISO-certified standards, trusted by worldwide partners.

Our solutions combine cost-effectiveness and long-term performance for extreme-reliability sectors.

Discover how our bearing housing innovations may improve operations and save downtime.

We constantly provide detailed technical assistance and fast service.

FAQs

1. What are Mechanical Parts Bearing Seat materials?

Wuxi Kaihan Technology makes cast iron, stainless steel, and engineered polymer bearing seats. Automotive and heavy machinery sectors benefit from these materials' durability, corrosion resistance, and performance. Global clientele receive consistent quality from ISO-certified procedures.2. Which businesses use custom Bearing Seats?

Mining equipment and wind turbines use our bearing housing components for accuracy and dependability. With 20+ years of technical experience, custom designs meet particular load capacities, temperatures, and space limits.3. What is your customisation process?

Communicate dimensions, material choices, and industry norms. We make 3D models for approval and prototypes for testing. Quick adjustments are done to match particular demands before mass manufacturing.4. What quality requirements guarantee product reliability?

Each bearing seat is checked for dimensional correctness, surface quality, and stress tolerance. To integrate with worldwide machinery systems, we follow ISO 9001 and industry-specific certifications.5. How can I bulk-order Mechanical Bearing Seats?

Send us your requests via email or our website. Contact us within 24 hours for a price, lead time, and manufacturing status. Need help now? Our team helps with installation and after-sales. Contact us for unique solutions now!

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email