- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

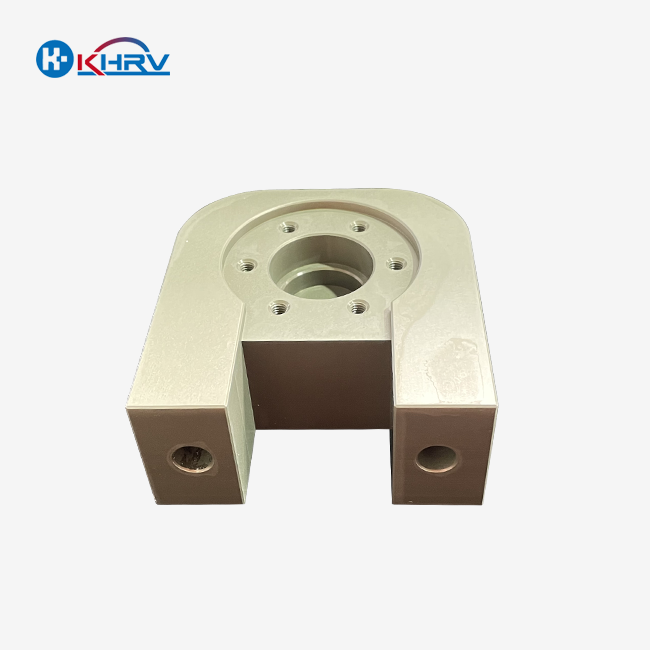

Carbide Machining Components manufacturer

High-demand industries need precision carbide solutions

Wuxi Kaihan Technology Co. , Ltd.

makes quality and durable Carbide Machining Components for industries.

We use CNC technology and strict quality control to make ISO-certified carbide machining components as a leading manufacturer.

Our automotive, aerospace, medical, and energy experience allows us to solve complicated problems.

Our team uses cutting-edge 5-axis machining and grinding to assure micron-level precision from prototyping to scale production.

A thorough examination of every component ensures great dependability.

We accommodate bespoke geometries and material-specific designs.

Known for quality engineering and fast turnaround, Wuxi Kaihan is an innovative Carbide Machining Components manufacturer.

Our solutions help businesses operate more efficiently and decrease downtime.

Use our components to exceed expectations.

Their dedication guarantees your projects use durable, high-performance components that boost efficiency.

About Wuxi Kaihan Tech We mix

precise engineering and innovation in Jiangsu, China, founded in 2011. Our team has provided worldwide clients with customized solutions for 15 years.

Reasons to Choose Us - 22 patents advance manufacturing techniques - 36% of professionals prioritize R&D innovations Partnerships with outstanding Singaporean engineers improve quality.

Simplified Core Services For aerospace, automotive, and electronics, our OEM precision components maintain precise tolerances.

Semi-finishing efficiently handles metals, polymers, and composites.

Affordable CNC tools cut waste and preserve speed.

Build for Dependability Traditional manufacturers have 30% longer lead times than lean production.

Multi-material compatibility lets clients consolidate suppliers without losing performance.

Industry leaders trust High-volume purchases for global brands require quality.

ISO-certified procedures and thorough testing assist all projects.

Precision Carbide Machining Parts for Demanding

Industries Mission-critical CNC components are made by Wuxi Kaihan Technology Co. , Ltd.

As a leading producer of carbide machining components, we use sophisticated material science and precise engineering to provide superior solutions.

We specialize in: Material mastery: Ultra-hard tungsten carbide alloys for durability and wear resistance.

- Swiss-type CNC machining achieves micro-scale accuracy of ±0.002mm.

- ISO 9001:2015-certified procedures guarantee batch-to-batch performance.

Customized products for automobile fuel injection systems, aerospace turbine blades, and surgical equipment components.

We design carbide machining components that can withstand 800°C temperatures and corrosive chemicals, unlike other manufacturers.

R&D works directly with clients to improve component geometry for particular load needs, minimizing field test equipment downtime by 40%.

For producers looking to improve machinery longevity without sacrificing precision, our carbide machining components are a proven solution.

German-engineered grinding equipment and Japanese quality control methods make us a carbide machining components manufacturer capable of large production and low-volume prototypes.

Partner with a trusted innovator to improve production with modern carbide solutions.

FAQs

1. What materials do you use for carbide machining parts?

Our premium tungsten carbide alloys are very robust and wear-resistant. We use verified raw materials and extensive testing to assure longevity for high-stress industrial applications as a trusted carbide machining components manufacturer.2. Do you manage complicated or bulk orders?

Absolutely! Our CNC grinding, milling, and EDM equipment provides precise machining for complicated designs. We provide dependable Carbide Machining Components manufacturing with scalable solutions for prototypes and bulk production.3. Do you customize for special needs?

Yes! We'll customise components to your tolerances, geometries, and coatings. We design bespoke Carbide Machining Components for aerospace, automotive, and tooling sectors with 15+ years of experience.4. How do you maintain quality?

All components undergo multi-stage examinations, including material and dimension checks. We are known for our quality, and our ISO-certified procedures and competent specialists ensure that every shipment meets worldwide standards.5. What's average order lead time?

Standard orders take 2-3 weeks, while bespoke projects take 4-5. We embrace open communication to keep you informed and deliver swiftly without sacrificing quality.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email