- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

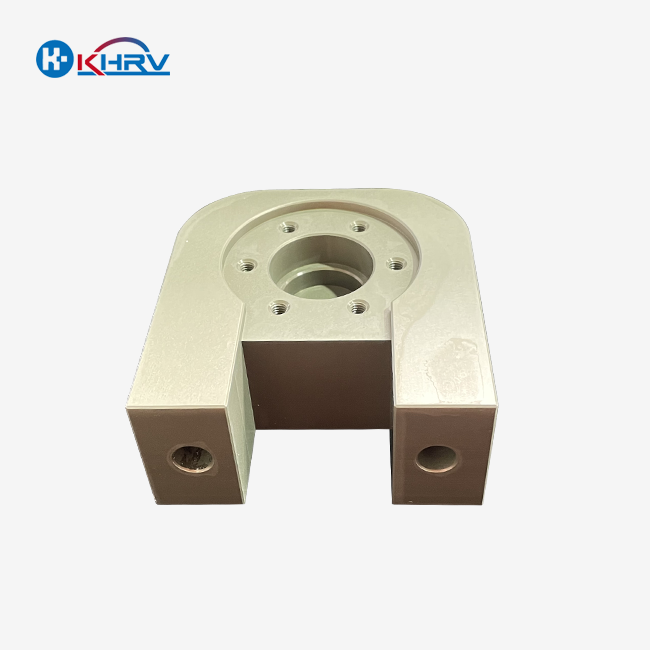

Milling Cutter For Stainless Steel manufacturer

Precision Milling Cutters for Stainless Steel

Wuxi Kaihan Technology Co. , Ltd.

is a reputable Milling Cutter For Stainless Steel manufacturer that makes high-performance equipment for industrial use.

Advanced coatings like TiAlN and AlCrN decrease tool wear and provide smooth, burr-free finishes in our products.

Precision geometry gives these cutters outstanding endurance in stainless steel cutting, even under severe loads.

We focus CNC machine compatibility as a leading **Milling Cutter For Stainless Steel** manufacturer for quicker feed rates and reliable outcomes.

Our staff customizes solutions to fit your process, whether you require custom edge preparations or measurements.

Every ISO 9001 and CE-certified tool is rigorously tested to satisfy worldwide quality requirements.

The enhanced chip evacuation design reduces heat buildup, increasing tool life and enhancing surface smoothness.

Wuxi Kaihan innovates and controls quality for businesses seeking trusted **Milling Cutter For Stainless Steel manufacturer** collaborations.

Discover how our stainless steel machining tools may improve results.

In 2011, Wuxi Kaihan Technology provided precision solutions

Expertise Built 15+ Years Established in Jiangsu, China, we combine innovation and production expertise. With 22 patents and Singaporean expertise, our team provides cutting-edge R&D.

Better Manufacturing for Global Partners We offer customized OEM solutions in multi-material semi-finishing and precision components.

Lean production reduces waste and ensures quality.

Affordable CNC machines improve productivity for metal, plastic, and composite products.

Each product is rigorously tested to meet worldwide industry standards.

### Industry leaders trust 36% of our staff works on R&D, improving tool durability and machining efficiency.

Performance is constant across batches thanks to advanced quality control.

We provide reliable solutions that connect complicated concepts and large production realities, keeping manufacturing lines operating smoothly.

Precision Milling Stainless Steel Wuxi Kaihan Technology Co

, Ltd. develops a tough stainless steel milling cutter.

Professional producers employ cutting-edge technology and high-quality materials for precision and durability.

Our stainless steel tools include advanced coatings that reduce heat and workpiece adherence.

By optimizing flute form, chip tangling is decreased and vibration-resistant qualities stabilize at high speeds.

Smoother finishes and extended tool life save costs and downtime.

Our Milling Cutters include ultra-hard coatings for wear and heat protection, perfect geometry for chip evacuation, and increased vibration dampening for error-free milling.

Drug-coating synergy extends life.

Personalized project solutions We prioritize quality control and R&D as a leading Milling Cutter For Stainless Steel manufacturer to meet industry requirements.

Austenitic, martensitic, and duplex stainless steels are employed in complex shapes.

Our solutions increase feed rates and surface finishes with tight tolerances for precise operations.

These cutters are durable and adaptable, making them ideal for aerospace, automotive, and industrial applications.

Technicians can recommend or customize stainless steel machining tools.

Experts make all projects cost-effective.

High-performance tools need decades of engineering and manufacturing.

FAQs

1. What makes stainless steel hard to machine?

How do your milling cutters help? Stainless steel's toughness and work-hardening require specific tools. For heat reduction, wear resistance, and sharp edges, our milling cutters use micro-grain carbide substrates and TiAlN coatings. We optimise geometry for chip evacuation and tool deflection as a reputable stainless steel milling cutter manufacturer.2. What coatings do you propose for stainless steel milling cutters?

We prefer AlCrN or TiSiN coatings for tool longevity. In hot settings, these coatings reduce friction and inhibit adhesion. ISO 9001-certified Wuxi Kaihan methods enable perfect coating adherence and thorough quality tests for reliable performance.3. Can milling cutters be customized for stainless steel machining?

Absolutely! We develop bespoke flute counts, helix angles, and edge preparations with 15+ years of experience. Our engineers work together to address problems with aircraft alloys and medical-grade stainless steel.4. How does your quality control guarantee milling cutter reliability?

Hardness, coating thickness, and cutting-edge microscopy are performed on every tool. We are a renowned stainless steel milling cutter manufacturer that follows DIN/ANSI standards and provides material traceability. Compliance with ISO 9001 and environmental management are our certifications.5. Why cooperate with Wuxi Kaihan for milling cutters?

We use cutting-edge R&D and hand-on machining. Our tools last 20% longer in stainless steel, with 24/7 technical support and fast global shipping. Ready for production optimization? Contact us immediately for a customized solution!

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email