- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

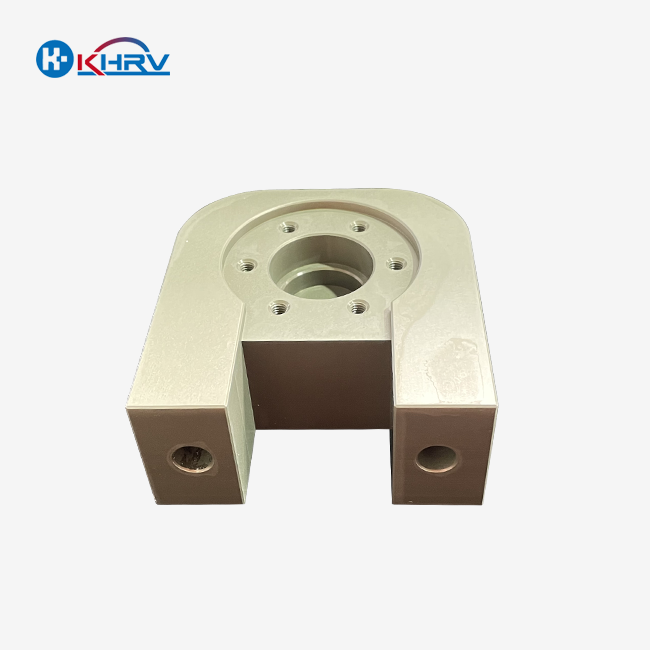

CNC Turning Metal Machining Parts manufacturer

Precision CNC Machining for Industry Wuxi

Kaihan Technology Co. , Ltd.

manufactures precision CNC turning metal machining parts for automotive, aerospace, and medical sectors.

To achieve dimensional precision and repeatability, our ISO-certified plant uses multi-axis CNC turning and strict quality control.

From prototyping to large manufacturing, we handle complicated stainless steel, aluminum, titanium, and engineering plastic shapes.

Our materials knowledge allows us to create lightweight aeronautical components and corrosion-resistant medical equipment to your technical demands.

Stringent inspection methods ensure international standards are met for every project.

Our fast turnaround and low price make us a trusted partner for urgent small quantities and large orders.

We combine creativity and pragmatism to create mission-critical, pressure-resistant parts for over a decade.

Advanced production and prompt service ensure your precise components arrive on time without sacrificing quality.

Precision Engineering Excellence Innovative Solutions Since

2011 Our Jiangsu, China-based high-tech company combines cutting-edge R&D and production. Our 22 patented ideas are supported by a talented workforce with 36% emphasis on innovative technology and over a decade of experience.

Global Collaboration, Local Expertise Precision components for many sectors are produced using top Singaporean experts.

Our lean manufacturing processes provide quality and cost for semi-finished multi-material components and high-performance CNC equipment.

Industry leaders trust We optimise automotive, aerospace, and electronics operations with OEM precision machining.

Every product undergoes thorough testing and practices sustainability.

Budget-Friendly Customization Flexible manufacturing accommodates small and big orders.

Advanced tooling reduces waste, supporting worldwide partners' efficiency goals.

Their technologies assist worldwide partners save manufacturing costs and preserve quality in aerospace and automotive.

Industrial Component Precision CNC Turning Wuxi

Kaihan Technology Co. , Ltd.

makes high-performance CNC Turning Metal Machining Parts with 5-axis capability and strict quality control.

For sectors like automotive, aerospace, and robotics that require strict tolerances and material integrity, our ISO-certified production provides perfection.

Technology Expertise We handle difficult stainless steel, aluminum, and exotic alloy geometries on multi-axis CNC lathes.

Real-time monitoring maintains consistency, while our experts optimize designs for efficiency without compromising durability.

Quality Guarantee Dimensional, surface polish, and material tests are performed on every component.

We produce defect-free items batch after batch with ISO 9001 certification.

Modified Manufacturing Process We meet your demands from prototype to mass manufacturing.

Share your CAD files or sketches—our team gives DFM feedback within 24 hours for cost-effective bespoke metal components.

Applications across industries We offer CNC turning for hydraulic fittings, sensor housings, and engine parts in harsh conditions.

Fast turnaround and 24/7 engineering assistance keep projects on track.

We combine innovation and dependability in precision machining.

Explore global-standard scalable solutions to improve production.

FAQs

1. What CNC turning materials do you offer?

We employ engineered alloys, stainless, brass, titanium, and aluminum. Our expert CNC Turning Metal Machining Parts manufacturer picks materials based on project strength, corrosion resistance, and temperature requirements. We'll suggest the best solution for you.2. Is your CNC manufactured part precise?

CNC lathes with sophisticated capabilities reach ±0.005 mm tolerances. Wuxi Kaihan's 15+ years of machining experience guarantees every metal item meets specs. We prioritize precision for prototypes and high-volume orders.3. Do you do bespoke CNC turning?

Absolutely! Customization is our forte. Our experts will optimise performance and cost from your CAD files or drawings. We accommodate custom geometries, surface treatments, and threading as CNC Turning Metal Machining Parts manufacturers.4. What quality checks do you undertake?

Raw material testing, in-process measurements, and final dimensional verification are done on every batch. ISO 9001-certified, we employ CMM equipment for precision. Detailed reports will verify your items satisfy industry requirements.5. What industries do you service with CNC turned parts?

Automotive, aerospace, medical, robotics, and energy applications employ our parts. Our hydraulic fittings and sensor housings are sturdy and precise. We provide fast-track alternatives for urgent jobs without sacrificing quality.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email