- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

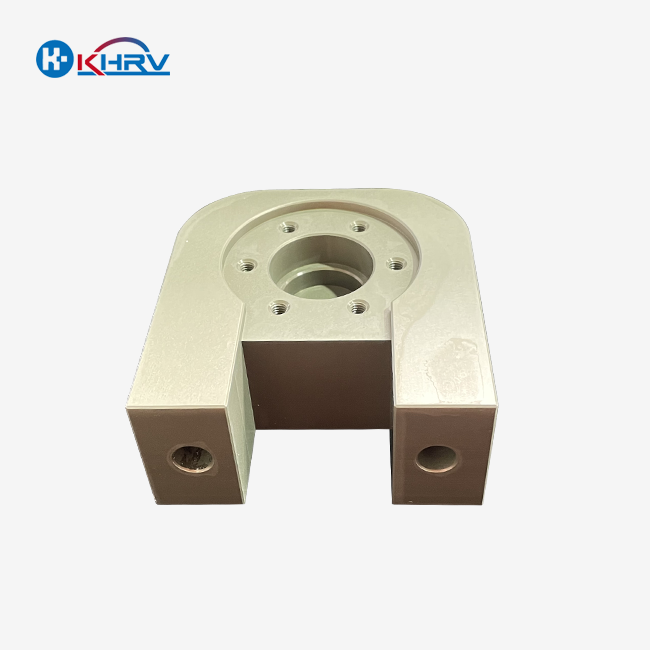

Eye Mold Holder manufacturer

Precision Eye Mold Holders for Industry

Excellence Eye Mold Holders from Wuxi Kaihan Technology Co. , Ltd.

are reliable for optical manufacturing accuracy.

We use modern CNC machining and 25+ years of experience to make Eye Mold Holders that satisfy industry requirements.

Why Use Our Eye Mold Holders?

Aerospace-grade materials make our products durable in high-pressure molding.

Each item is quality-checked with 3D measurement and surface analysis to ensure dimensional correctness below 0.005mm.

Custom Solutions for Varying Needs Our company customizes eye mold holders for medical devices and automobile lenses.

Rapid prototyping reduces lead times without sacrificing precision.

Trusted throughout industries From eyeglass lenses to camera optics, our components enable healthcare, electronics, and automotive makers.

ISO 9001 and traceable material certificates demonstrate our quality commitment.

Work with precise engineers who care about your production success for top performance.

Wuxi Kaihan Technology: Precision Engineers #innovation

Since 2011 Wuxi Kaihan Technology, founded in Jiangsu, China, combines innovative R&D and production. The team has provided precision solutions to global industry leaders for over 15 years.

Expertise You Can Trust A committed team—including top Singaporean engineers—drives innovation.

With 36% R&D workers and 22 patents, technical superiority is assured.

Custom Solutions for Every Need The OEM precision component processing firm does multi-material semi-finishing with unsurpassed accuracy.

Cost-effective CNC tools boost output without sacrificing quality.

Lean Production, Global Impact Lean manufacturing reduces waste and increases efficiency.

Fast turnaround and stringent quality control are supported by this method.

### Industry leaders trust Clients in automotive and aerospace want constant performance and adaptability to complicated project requirements.

All solutions combine technical perfection and cost-effectiveness.

Top Eye Mold Holder Manufacturer Solutions

With a focus on dependability, Wuxi Kaihan Technology Co. , Ltd.

designs precise Eye Mold Holders.

As a reputable Eye Mold Holder manufacturer, we use modern CNC machining and material science to fulfill medical, electronics, and automotive specifications.

Precision Engineering for Many Uses Our Eye Mold Holder production process includes ISO-certified quality control, 3D scanning, and stress testing.

Our solutions adapt smoothly to micro-molding and industrial tooling needs.

Customized Solutions for You Each project is unique.

We customise designs, materials (such stainless steel or aluminium alloys), and surface treatments to your specifications.

Our engineers work together to streamline functionality without sacrificing durability.

Thorough Quality Control Raw material verification, in-process dimensional checks, and performance validation are done on every batch.

This meets global RoHS and REACH regulations.

Industry-Specific Knowledge From optical lens production to semiconductor molding, our Eye Mold Holder maker team knows specific issues.

Precision, downtime, and mold lifecycles are improved by our components.

Request comprehensive specs to investigate production line solutions.

FAQs

1. What distinguishes your Eye Mold Holder manufacturer?

Precision engineering and durable materials are our specialties as a leading Eye Mold Holder manufacturer. Our products align molds smoothly, decreasing downtime. Our customizable designs and rigorous quality inspections make us a global industry partner.2. Can you make unique Eye Mold Holders?

Absolutely! Personalized designs are our specialty. From unusual dimensions to specialty coatings, our production knowledge guarantees your Eye Mold Holder works perfectly. Tell us your needs, and we'll do the rest.3. How does your Eye Mold Holder maker assure quality?

Hardness, wear resistance, and fit are tested on every product. ISO standards and modern CNC machines are used. Quality is assured by a qualified Eye Mold Holder manufacturer.4. What industries benefit from your Eye Mold Holder expertise?

We serve precision-focused automotive, electronics, and medical industries. Our 12+ years as a global Eye Mold Holder manufacturer provide efficient and durable solutions for varied applications.5. Why buy Eye Mold Holders from Wuxi Kaihan?

Beyond cutting-edge technology, we value collaborations. We stand out with fast response, affordable price, and 24/7 assistance. Eye Mold Holders from our team can boost your production line.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email