- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

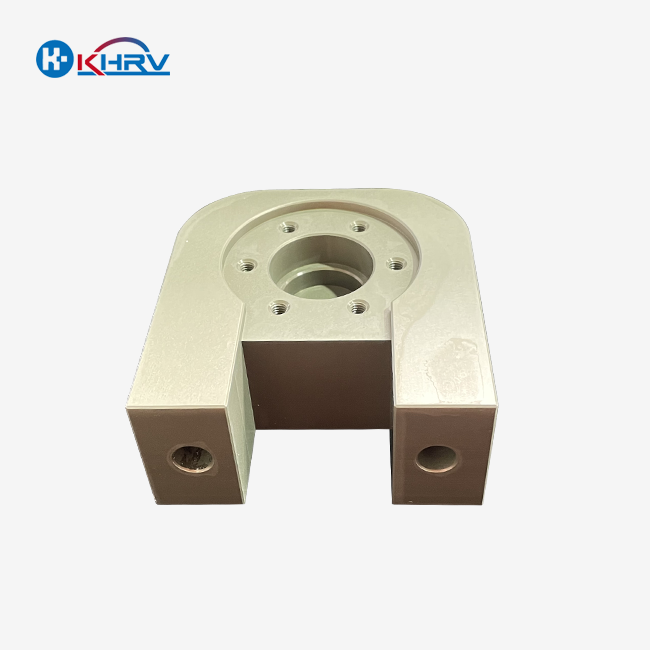

Customized Medical Device Components manufacturer

Wuxi Kaihan Technology Co

, Ltd.: Your Precision Medical Manufacturing Partner Profile of company Wuxi Kaihan Technology Co., Ltd.

is a reputable manufacturer that provides customized medical device components to global clients.

We follow medical sector norms and use modern CNC machining with ISO 13485 and ISO 9001 certifications.

### Key Skills Our specialty is manufacturing customized medical device components for surgical and diagnostic equipment using multi-axis CNC systems for difficult geometries.

Safe patient-contact materials meet ISO 10993 biocompatibility standards.

QA Each component is rigorously validated from design to final inspections.

We comply with regulatory requirements in Europe, North America, and Asia-Pacific markets by implementing traceability processes and sterilization-ready finishes as a certified manufacturer.

Start here for reliable surgical and diagnostic device innovative solutions.

Precision engineering expertise We provide sophisticated

manufacturing solutions using innovation and craftsmanship in Jiangsu, China, founded in 2011. Our 15 years of experience drives our ambition to change industry norms with cutting-edge technology.

## Innovation Central We advance precise engineering with 22 patents and a 36% innovative R&D staff.

Global expertise meets local excellence through top Singaporean collaborations.

Efficiency-Driven Solutions Our lean manufacturing procedures maximize quality and reduce waste in multi-material semi-finishing and bespoke precision products.

Cost-effective CNC machines let enterprises do more with less.

Global Leaders Trust Our dependability has gained us collaborations with prominent manufacturers in automotive and aerospace.

Every part has been tested and is committed to sustainable improvement.

Intelligent design and reliable engineering make advanced manufacturing affordable.

Precision Medical Devices A creative maker

of trustworthy **Customized Medical Device Components** provides clinical compliance. Wuxi Kaihan Technology Co., Ltd.

makes medical-grade components using CNC machining, micro-molding, and biocompatible materials.

Our experts assist clients improve design for manufacturability, cost, and performance at our ISO 13485-certified facility.

We make surgical tools, implanted components, and diagnostic device assemblies using medical-grade polymers, metals, and ceramics for safety and endurance.

We prioritize openness from concept to production as a client-focused company.

Tight testing and documentation decrease time-to-market risks by ensuring every batch fulfills specifications.

Our Customized Medical Device Components knowledge covers complicated design concepts and real-world reliability after over a decade serving major medical brands.

Patients-first collaborations are trustworthy.

FAQs

1. What makes Kaihan Technology a reliable Customized Medical Device Components manufacturer?

Precision manufacturing and industrial knowledge are combined at Wuxi Kaihan Technology Co., Ltd. Our ISO 13485-certified facility guarantees every component meets medical standards, and our collaborative approach customizes solutions to your clinical demands.2. Could you tell me the materials used to make the parts of your medical machines?

Silicon, stainless steel, and biocompatible polymers made for medical usage are utilized. Kaihan Technology prioritizes device performance, sterilization, and regulatory compliance while choosing materials. This ensures that their products are long-lasting and safe for patients.3. How does your quality control system guarantee reliability?

We use 100% traceability and multi-stage checks from prototype to large manufacturing. Kaihan Technology, a leading Customized Medical Device Components manufacturer, ensures dimensional correctness and performance consistency with automated and manual testing.4. Can you prototype and mass-produce?

Fast prototyping validates designs, then scaling to high-volume volumes is our specialty. Mid-process alterations in our flexible production methods keep your bespoke components cost-effective and high-quality.5. How do you customize at your facility?

Your device's clinical applicability and compliance demands are assessed first. Kaihan Technology engineers co-design components using CAD/CAM tools, select materials, and provide functioning prototypes within weeks, keeping you informed.

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email