- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

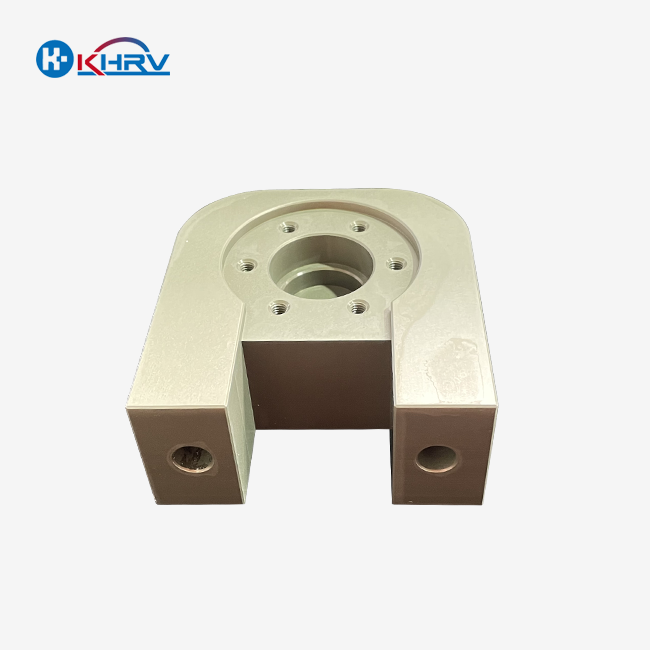

Rectangular Precision Machined Parts manufacturer

Your Reliable Rectangular Precision Machined Parts

Manufacturer: Wuxi Kaihan Crafting rectangular precision machined parts requires material and tight tolerance engineering skills.

Wuxi Kaihan Technology Co., Ltd.

provides high-quality CNC machining services for automotive, aerospace, and medical sectors.

Material Excellence & Custom Solutions We use aerospace-grade aluminum, stainless steel, and titanium for durability and performance.

ISO-certified procedures provide consistency, while customisation lets you customize parts.

Rapid prototyping accelerates innovation Urgent OEM manufacturing solutions?

Rapid prototyping saves time without sacrificing precision.

We simplify startup and business workflows from inception to completion.

Quality that builds trust Every part is inspected to satisfy worldwide standards.

We focus dependability in automotive subsystems, surgical equipment, and aircraft components for low- and high-volume runs.

Visit www.kaihan-tech.com or email info@kaihan-tech.com for customized CNC machining services.

Our precision-engineered rectangular pieces will enhance your designs.

Since 2011, Precision Engineering Excellence Wuxi

Kaihan Technology in Jiangsu, China, combines innovation and craftsmanship to provide precise solutions. Over 15 years, we've collaborated with global industry leaders on sophisticated R&D and smart production.

We prioritize expertise and innovation, with 36% of our workforce focusing on R&D, including top Singaporean engineers.

- 22 patented technologies boost production efficiency - Lean manufacturing guarantees quality control Customized for Different Needs In multi-material semi-finishing and precision component processing, we optimize costs without sacrificing performance.

Our CNC tools are durable and affordable for long-term value.

Quality tests and ISO-certified procedures help every project, from prototype to production.

Over 50 global partners expect us to simplify complicated industrial problems.

In 12 specialized workshops, advanced automation and human experience provide fast turnaround for tailored orders.

This synergy sustains aerospace, automotive, and industrial customer growth.

We stand out in OEM production with reliable delivery times and material-specific engineering.

Each part represents 1,200+ hours of yearly R&D and cross-industry knowledge transfer.

Trustworthy Rectangular Precision Machined Parts Partner

Leading rectangle precision machined parts manufacturer Wuxi Kaihan Technology Co. , Ltd.

offers customized solutions for precision-intensive industries.

We provide CNC machining with ±0.005mm precision, manufacturing components from aluminum, stainless steel, titanium, and exotic alloys for high-performance needs.

Key technical specs: Tolerance: ±0.005mm to ±0.01mm - Materials: Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 2/5 - Surface Finishes: Anodizing, Powder Coating, Passivation Production From Prototype to Mass Production Customized lead time: 5-15 days ISO 9001 certification ensures high-quality aircraft actuators, medical implants, auto sensors, and industrial equipment.

We tailor solutions to complex geometries and high-strength designs.

Choose Us Reasons CAD review to post-processing in custom engineering.

Quality Control: 3D CMM, material tracking.

Responding: Project managers streamline communication.

Cost-effective Scaling: Process optimization saves time and waste.

Since 2010, we solve exact challenges for global clients using advanced machining centers and hands-on experience.

Our Rectangular Precision Machined Parts production expertise may boost your next project with reliability and innovation.

FAQs

1. Which industries profit from rectangular precision machined parts?

Aerospace, automotive, medical, and robotics require rectangular precision manufactured parts. To ensure dependability in high-performance applications, Wuxi Kaihan Technology Co., Ltd. crafts these components to rigorous tolerances. Our knowledge assists industries that require precision and endurance.2. How does Wuxi Kaihan assure production quality?

We employ ISO 9001 and sophisticated CNC equipment for dependable outcomes. All rectangular precision machined parts are inspected, including 3D measurement and surface analysis. Our quality and compliance dedication makes us a trustworthy manufacturer.3. Can you modify rectangular pieces for certain projects?

Absolutely! We provide bespoke rectangular precision machined components to your specifications. We work together to meet your project's needs for unusual materials, coatings, or shapes.4. What materials do these components typically use?

Aluminum, stainless steel, titanium, and technical polymers are used. Material choice depends on application criteria like corrosion resistance or lightweight strength. As a renowned manufacturer, we help you choose the optimal performance and cost-efficiency solution.5. Why pick Wuxi Kaihan as your manufacturer?

With decades of expertise, we blend cutting-edge technology with skillful craftsmanship. Our creativity, fast development, and on-time delivery make us a trusted rectangle precision machined part partner. Discuss how we may improve your next project!

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email