- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Precision Ball End Mill manufacturer

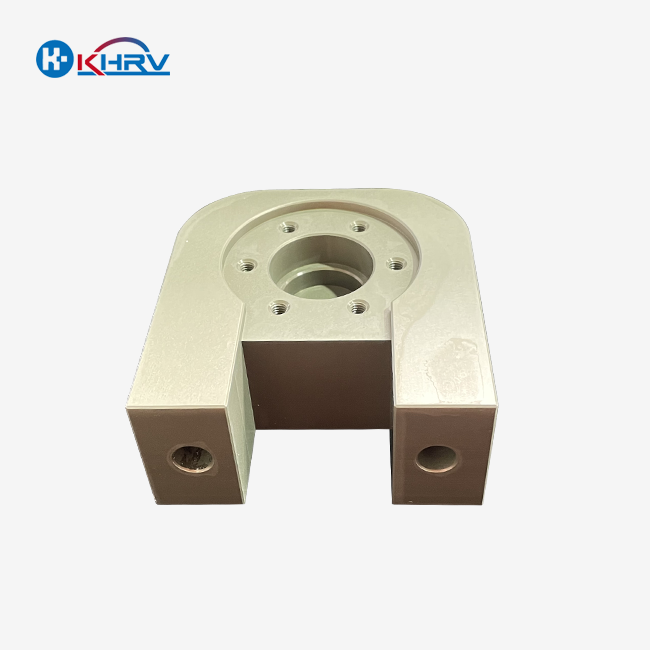

Wuxi Kaihan Technology: Your Precision Machining

Partner Leading Precision Ball End Mill maker Wuxi Kaihan Technology Co. , Ltd.

provides cutting-edge solutions for complicated machining problems.

With modern CNC grinding and strict quality control, we make robust, high-performance aerospace, automotive, medical, and mold tools.

Choose us for unmatched accuracy with tight tolerances (±0.002mm) for immaculate surface finishes.

Premium materials: Ultra-fine carbide and coatings prolong tool life.

Certified excellence: ISO 9001 methods provide reliability.

Our Precision Ball End Mills do detailed contouring and 3D machining with 24/7 technical assistance and unique design.

As a recognized Precision Ball End Mill manufacturer, we innovate to suit industry demands and follow worldwide environmental requirements.

Browse our collection or request a quotation for accurate, durable, and affordable instruments.

The perfect answer for your toughest challenges is a chat away.

Since 2011, Precision Engineering Solutions has

provided innovative manufacturing expertise. This dynamic Jiangsu, China-based company has 15 years of technical expertise and cutting-edge R&D.

It specializes in precision component processing and semi-finishing with over two dozen unique methods.

Global Standards, Local Efficiency Research and development accounts for 36% of a Singaporean-enhanced engineering workforce, creating innovation.

CNC and custom machining services with multi-material compatibility are quality-controlled.

Trusted by Industry Leaders Lean manufacturing methods provide precise, cost-effective tooling.

From prototyping to mid-volume batches, advanced manufacturing processes serve micrometer-accurate industries.

Stainless steel, titanium, and specialty alloys work consistently thanks to exclusive quality assurance processes and material science expertise.

Operations optimize manufacturing times and produce components that meet strict international standards.

Demanding Industry Precision Ball End Mill

Solutions The correct Precision Ball End Mill manufacturer is crucial for difficult machining jobs that need unrivaled accuracy.

Wuxi Kaihan Technology Co., Ltd.

makes high-performance carbide end mills for aerospace, automotive, and medical device industries.

To achieve excellent surface finishes and prolonged tool life, our precise engineering ensures every tool satisfies tolerances under 5µm.

Ultra-fine carbide substrates make our ball end mills wear-resistant in high-temperature conditions, minimizing downtime and costs.

We provide CNC milling solution customisation beyond conventional designs.

To improve chip evacuation, vibration management, and material performance, we change helix angles, flute counts, or coatings like AlTiN.

Our prototyping and mass manufacturing skills are trusted by high-precision cutting tool manufacturers.

From titanium aircraft components to hardened steel molds, we combine speed and precision.

ISO-certified methods and rigorous quality inspections ensure batch consistency.

Trusted expertise for difficult machining.

FAQs

1. Which industries utilize Wuxi Kaihan Technology Precision Ball End Mills?

Our Precision Ball End Mills are perfect for aerospace, automotive, medical, and mold-making. We create equipment for complicated 3D contouring and fine-detail machining in hardened steels, alloys, and composites as a trusted manufacturer.2. What materials can your Precision Ball End Mills handle?

They work with titanium, aluminum, stainless steel, and high-temperature alloys. Wuxi Kaihan Technology premium carbide coatings last in tough applications.3. What makes your Precision Ball End Mills better than competitors?

We focus strict tolerances (±0.002mm) and enhanced helix angles for smoother finishing as a specialist producer. Our tools decrease vibration and wear, saving time and money.4. Can you modify Precision Ball End Mills for special projects?

We customize flute lengths, coatings, and shanks. Share your machining needs, and our staff will design solutions.5. How can I maintain these equipment for longevity?

Avoid high feed rates and clean chips often. Contact Wuxi Kaihan Technology for lifetime regrinding and troubleshooting. Count on our 15+ years of precise tooling!

Best Selling Products

Related Blogs

Related Search

Telephone:+8615951511692

Email:service@kaihancnc.com

Learn about our latest products and discounts through SMS or email